Handling robot packagingbag palletizingfilling

Add to favorites

Compare this product

Characteristics

- Function

- handling, packaging, bag palletizing, filling

- Mounting

- floor-mounted

- Application domain

- for the food industry

- Other characteristics

- compact, high-speed, autonomous

Description

We have developed a powerful and flexible system using an industrial robot for handling valve bags. Valve bags are a very popular packaging solution for many different industries such as dry building materials, fertilizers, food, minerals, chemicals. They have an opening valve in one corner through which the sack is filled. Key advantages are their applicability for high-speed filling and the box type sack that they produce one filled. It sits very stable and allows the palletizing of many bags on a single pallet. Furthermore, the bag closes by itself and there is no need for sewing, sealing or other similar operation, which costs both time and money.

However, a disadvantage of many of the smaller and mid-sized bag filling machines is that they have to be tended manually. An operator has to stand next to the machine and apply the empty bags. It is a highly repetitive job and when the operator gets bored and distracted, it has a negative impact on the cycle time.

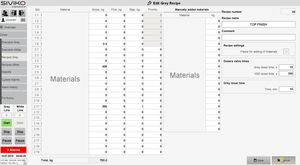

We have developed an automated robotic solution for handling and applying empty valve bags to packer spouts. It features a FANUC M-10iD industrial robot that reaches the highest axis speed and precision in its class. The robots use a specialized gripper designed for this particular application. It picks up the bags, opens them and places them on the packer spouts. It works in coordination with the filling machines. The system has an empty bag feeder that can accommodate dozens of different types of bags, offers a long period of autonomous working and saves a lot of space with compact size.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Siviko OOD‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.