- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

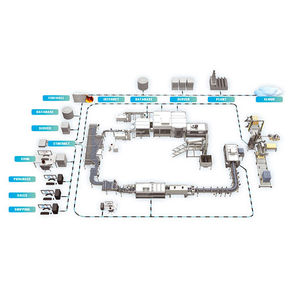

Sustainable bottling and packaging line

Add to favorites

Compare this product

Characteristics

- Options

- sustainable

Description

ENJOY A VIRTUAL TOUR INSIDE SMI SUSTAINABLE CARTON AND FILM PCKAGING LINE

Get your access here:

https://www.smigroup.it/profilo/smi-virtual-showroom?lang=en

An interactive tour, in which you can discover two complete lines.

Thanks to the wide range of SMI stretch-blow moulders you will be able to manufacture containers of different shapes and sizes, from 0.10 L up to 10 L, in PET or rPET.

The advantages of these machines are further enhanced, when the blower is combined with a filler and a capper, which means considerable advantages in terms of space, energy and cost saving. After the bottle is produced, there are several packaging solutions SMI can offer: film and cardboard packaging are just two examples.

Solution 1:

By clicking on the first line, you will be able to find out the advantages of our shrink wrappers, capable of packing a wide range of containers and of processing standard or 100% recyclable film.

Solution 2:

By selecting the second line, you will find out our new ACP case packers, capable of packing a wide range of containers in RSC boxes: an excellent choice for protecting your products. The end-of-line operation is made efficient by our palletizing systems, composed of several modules configurable in a customized manner.

All SMI machines are equipped with IoT technology, so that production and operating parameters are recorded, analyzed, optimized and automatically changed; the machines that are part of the same line exchange data and information and self-diagnostic tests are run to detect and solve faults or anomalies. This allows to monitor in real-time the industrial plant efficiency and to intervene remotely in case of problems.

VIDEO

Catalogs

No catalogs are available for this product.

See all of SMI Group‘s catalogsRelated Searches

- Packing machine

- Automatic filler

- Automatic packing machine

- Liquid filler

- Packing machine for the food industry

- Palletizer

- Volumetric filler

- SMI shrink wrapping machine

- SMI automatic shrink wrapping machine

- Complete packaging line

- Automatic palletizer

- SMI case packer

- Robotic palletizer

- SMI automatic case packer

- Packaging machine for the pharmaceutical industry

- Automatic complete packaging line

- SMI shrink wrapping machine with shrink tunnel

- Cartoner

- Compact filler

- High-speed packing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.