- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

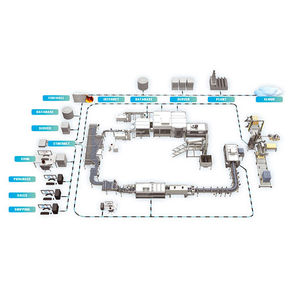

Compact complete packaging line for the beverage industryfor bottlesautomatic

Add to favorites

Compare this product

Characteristics

- Application domain

- for the beverage industry

- Product applications

- for bottles

- Other characteristics

- automatic, compact

Description

SMI's System Engineering Department offers complete bottling and packaging lines equipped with cutting-edge technical solutions for energy saving and TCO (Total Cost of Ownership) reduction.

The innovations devised by SMI designers enable to dramatically cut the production costs of each PET bottle manufactured in the plant, thanks to specific devices designed to save energy and streamline production cycles every machine is equipped with.

In more detail, a compact bottling line is made up of two blocks of machines whose high integration enables to cut space requirement, costs and consumptions:

- the first block is composed of an ECOBLOC® system, gathering into a single unit the functions of stretch-blowing, filling and capping (also labelling upon request);

- the second block, called PACKBLOC and specific for the end-of-line packaging, is composed of an automatic machine for secondary packaging integrated with a two-Cartesian-axis automatic palletizer.

If compared to traditional bottling plants made up of more "stand-alone" machines linked together by long stretches of conveyour belts, the compact lines enable to reduce the TCO thanks to:

- lower initial investment, since the two multi-tasking ECOBLOC® and PACKBLOC units allow to remarkably cut the length of the conveyor belts installed in the bottling and packaging plant;

- lower personnel costs, since the two machines performing all of production operations can be run and controlled by a reduced number of operators;

- fewer interventions of machine maintenance and cleaning and lower consumption of spare parts;

- energy costs cutting, since only high-efficiency and low consumption motors are used.

VIDEO

Catalogs

No catalogs are available for this product.

See all of SMI Group‘s catalogsRelated Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Liquid filler

- Packing machine for the food industry

- Palletizer

- Volumetric filler

- SMI shrink wrapping machine

- SMI automatic shrink wrapping machine

- Complete packaging line

- Automatic palletizer

- SMI case packer

- Robotic palletizer

- SMI automatic case packer

- Packaging machine for the pharmaceutical industry

- Automatic complete packaging line

- SMI shrink wrapping machine with shrink tunnel

- Cartoner

- Compact filler

- High-speed packing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.