- Electricity - Electronics

- Electronic Component

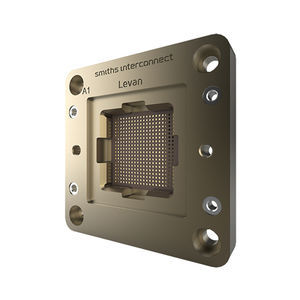

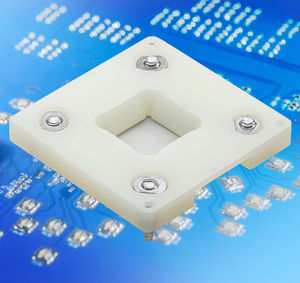

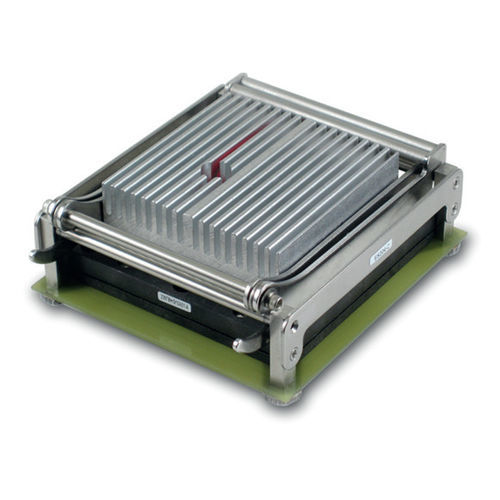

- Burn-in test socket

- Smiths Interconnect

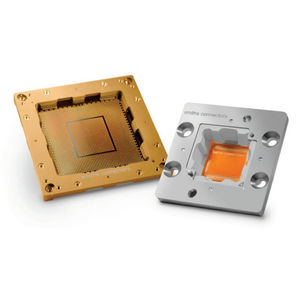

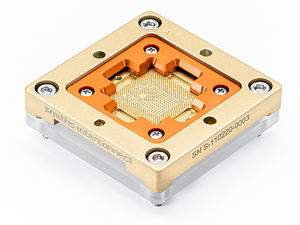

Burn-in test socket ES Series H-Pin®

Add to favorites

Compare this product

Characteristics

- Options

- burn-in

Description

ES family Series of sockets extended the scope of a burn-in socket. The modular lid construction can handle up to 1 kW of power and is optimized with thermal simulation to ensure out-of-the-box performance whether liquid or air cooled. Leveraging a variety of advanced manufacturing techniques and industry-leading automation enables the lowest cost of test. Our patented H-Pin technology provides versatility in the socket application which can be used for ATE and SLT functional testing, in addition to covering the full gambit of burn-in test applications. The ES family Series of sockets is designed for use with all advanced burn-in systems. With adaptation comes unmatched value in delivering cutting-edge technology.

Features & Benefits

- Configurable design, large tooling catalog, molding, machining, 3D printing, and assembly automation deliver best-in-class quality, price, and lead times.

- An extensive catalog of standard components provides field-tested designs.

- Double-latching clamshell provides ease of use during operation for high pin count applications.

- Thermal and electrical simulation, Monte Carlo and FEA all ensure the delivery of out-of-the-box solution.

Feature Options

- Spring loaded plunger

- Heat sink

- HAST venting features

- Integrated thermal control with heater and sensor

- Reverse seating plane

- Maximum component clearance under the DUT

- High temperature materials for above 200 °C applications

Catalogs

ES Series H-Pin® Socket

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Smiths electronic filter

- Smiths transceiver

- Passive electronic filter

- Low-pass electronic filter

- Board-mount resistor

- Power resistor

- Smiths fiber optic transceiver

- High-speed transceiver module

- Band-pass electronic filter

- Thin-film resistor

- Thick-film resistor

- High-pass electronic filter

- Smiths multimode transceiver

- RoHS resistor

- SMD resistor

- Smiths test socket

- Data transmission transceiver module

- High-power resistor

- RF electronic filter

- Multi-channel transceiver module

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.