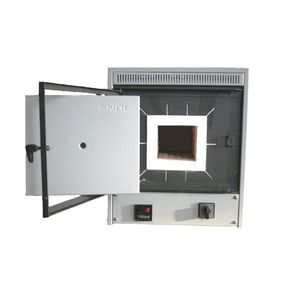

Chamber furnace 30/1100 LSF22ashingelectrichigh-temperature

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- ashing

- Heat source

- electric

- Other characteristics

- high-temperature, continuous, laboratory

- Maximum temperature

1,100 °C

(2,012 °F)- Capacity

30 l

(7.93 gal)- Width

645 mm

(25.39 in)- Height

835 mm

(32.87 in)- Depth

870 mm

(34.25 in)

Description

SNOL 30/1100 ashing furnace with a chamber made from fiber thermal insulation plates is designed for ashing and burn-off processes up to 1100°C. Fan-assisted chimney permits the elimination of smokes from the chamber during the process.

BASIC MODEL

• Chamber is made from fiber thermal insulation plates

• Embedded heating elements are in four sides around the chamber

• Fan-assisted chimney for smoke and humidity extraction

• Continuous air change in the chamber

• Door opens to the right

• Door safety interlock switch

• Microprocessor – temperature controller

• Outside casing – metal sheet, powder painted grey

• High quality, ecological thermal insulation material

• Low electric power consumption

• Short heating up/cooling down period

• High degree of accuracy

• 1 year warranty

OPTIONS

• Additional ceramic hearth plates

• Buzzer

• Protection against overheating

• Data recorder

• Data communication/USB

• Calibration of temperature measurement system

• Additional 1 year warranty

Technical data

Rated power not more than kW 3.4

Rated supply voltage V 230

Rated frequency Hz 50

Number of phases – 1

Working chamber material – Fiber plates

Maximum heating- up time (without charge) Min. 150

Temperature stability in working chamber at rated temperature in thermal steady state without charge not more than ± °C 1

Temperature uniformity in working space at rated temperature in thermal steady state without charge not more than ±°C 10

Furnace working chamber dimensions:

width mm 300

depth mm 405

height mm 275

Catalogs

No catalogs are available for this product.

See all of SNOL‘s catalogsRelated Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Laboratory furnace

- Stainless steel furnace

- High-temperature furnace

- Vacuum furnace

- Digital furnace

- Continuous furnace

- Annealing furnace

- Thermal furnace

- Melting furnace

- Horizontal furnace

- Sintering furnace

- Quenching furnace

- Muffle furnace

- Tubular furnace

- Hardening furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.