- Packing - Handling - Logistics

- Handling and Lifting

- Box lifting device

- Sohns Maschinenbau GmbH

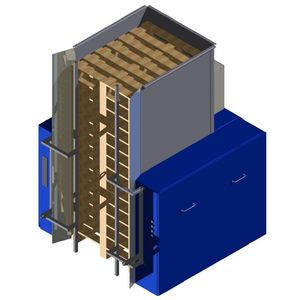

Box lifter BL10

Add to favorites

Compare this product

Characteristics

- Product applications

- for boxes

- Load limit

Max.: 60 kg

(132 lb)Min.: 0 kg

(0 lb)

Description

To feed machines manually, lifting and emptying heavy and bulky boxes is hard and dangerous for the operators. Some companies use feeding conveyors, but the boxes still need to be lifted and emptied manually. Therefore, we designed our Box Lifter, an automatic machine for feeding of parts and other goods, collected in boxes, which need to be lifted and rotated.

The Box Lifter is very easy to use. The ready boxes just need to be taken in the machine and it is working automatically. When ready, the operator pushes a button and the lift takes the box and moves to its turning / rotating position. A sensor gives a signal and the feeding process starts automatically. The box is turned automatically and its content goes directly into the feeder of the next machine. When the box is empty, the Box Lifter returns to its start position and the empty box can be exchanged with a full one. Then the process repeats again and again.

The box holder can be exchanged easily with another one, so the machine can handle boxes with different dimensions.

Our Box Lifter is an excellent solution for any production area. The automatic process makes the feeding easier and convenient for the operators. The risk of accidents and injuries is minimized. The work process is optimized and safe. Moreover, the machine has a compact form, which will help you to save space in your workshop.

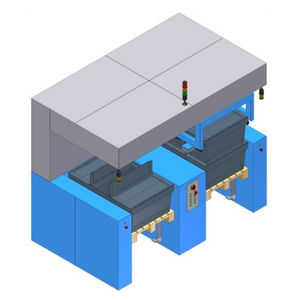

There are different options available, for example: an automatic box feeder, taking the boxes automatically on the box lifter; a box storage; conveying system and other special solutions.

TECHNICAL DATA

• Maximum load capacity: Up to 60 kg (depending on the box dimensions)

Catalogs

BL10

2 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.