- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

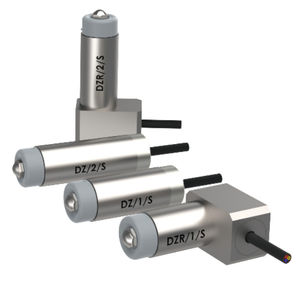

Angular position sensor Orbit LTlinearnon-contactlaser triangulation

Add to favorites

Compare this product

Characteristics

- Type

- linear, angular

- Contact / non-contact

- non-contact

- Technology

- laser triangulation

- Other characteristics

- compact, precision

- Measuring range

10 mm, 25 mm

(0.39 in, 0.98 in)- Measuring rate

4 kHz

Description

Non-Contact Laser Triangulation Sensors - High-Performance Lasers

The range of precision laser triangulation sensors that are fully Orbit Enabled are fully compatible with all Solartron Readouts and Gauging Software is ideal for highly reflective, metallic surfaces.

Excellent on Metallic and Reflective Surfaces

The laser performs extremely well on pieces of metal, even if they are reflective. This is partially due to an oval beam, which helps compensate for irregularities or roughness. We have demonstrated this laser to some customers, and it performed extremely well. One agent in China tested it by placing a mirror-like gauge block underneath the beam, and said it performed better than any other laser they had tried.

No Controller

Most Keyence laser units require an additional controller for their laser unit. For Orbit LT2, everything is self contained. This can help save costs.

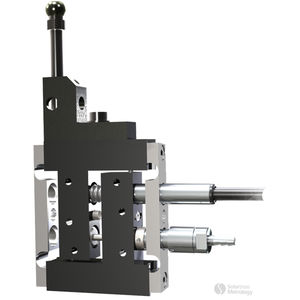

Orbit Connectivity

As with our past lasers, Orbit LT2 can be networked contact probes and other sensors via Orbit. This has been a key advantage for customers that want just one connection into a PC or PLC for all of their sensors.

Key features

LT1 and LT2 options available

High precision for metallic and reflective surfaces

"Oval spot that is ideal for checking metallic surfaces

"Adaptive Surface Adjustment"

Very compact 20 mm width

Drivers offer various measurement modes and averaging adjustment for peak repeatability

Measuring range LT1 - 25 mm, LT2 - 10 mm

Accuracy - better than 12 µm

Repeatability LT1 - 2.5 µm, LT2 - 0.5 µm

Resolution LT1 - 0.4 µm, LT2 - 0.15 µm

Sampling rate up to 4 kHz

Catalogs

No catalogs are available for this product.

See all of SOLARTRON METROLOGY‘s catalogsOther SOLARTRON METROLOGY products

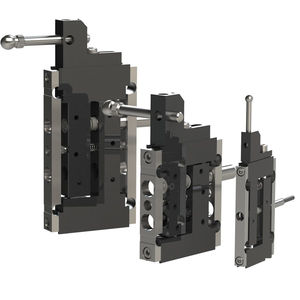

Orbit® Digital Measurement Network

Related Searches

- Incremental encoder

- Digital panel meter

- Position transducer

- Panel-mount panel meter

- Linear position transducer

- Solartron displacement sensor

- Solartron linear displacement sensor

- Non-contact position transducer

- Linear encoder

- Position panel meter

- Analog displacement transducer

- Signal conditioning module

- Compact position transducer

- Incremental linear encoder

- Rotary position sensor

- Precision position sensor

- Metal displacement transducer

- Optical linear encoder

- Solartron LVDT displacement sensor

- IP67 displacement transducer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.