- Metrology - Laboratory

- Metrology and Test Equipment

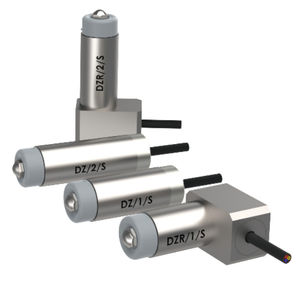

- Linear measurement touch probe

- SOLARTRON METROLOGY

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Digital touch probe DJ/P linear measurementpneumaticdigital

Add to favorites

Compare this product

Characteristics

- Type

- linear measurement

- Technology

- pneumatic

- Display

- digital

- Other characteristics

- digital

- Measuring range

Max.: 30 mm

(1.1811 in)Min.: 2 mm

(0.0787 in)- Resolution

0.01 µm

Description

Digital Gauge Probe | Pneumatic Piston Push (Jet) DJ/P

•2,5,10,20 and 30 mm displacement transducer measuring ranges

•Accuracy better than 0.1 µm

•Repeatability precision better than 0.05 µm

•Resolution better than 0.01 µm

•Range of contact sensor tips available

•Pneumatic actuation using internal piston – gaiter independent.

•Standard contact sensor tip force of 0.7N (other options available)

•IP50 sealing (fully sealed options available)

•Displacement sensor with excellent sideload capability

•Superior performance compared to traditional Linear Variable Differential Transformer (LVDT) displacement sensors

•High resistance to external magnetic fields which can interfere with measurements from typical LVDTs

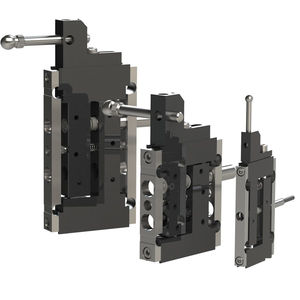

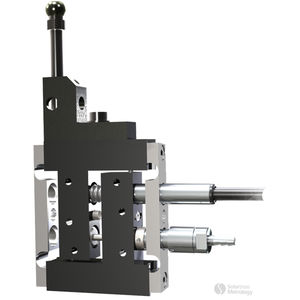

A pneumatic displacement sensor (gauge probe) allows the number of parts in the fixture to be reduced resulting in improved reliability and reduced fixture cost. It also allows for fast automatic loading of the part into the gauge as the displacement probe tip can be in the fully ‘retract position’ when this is occurring.

The benefit of using a pneumatic push displacement sensor (gauge probe) compared to a spring push probe is that there is less need to design mechanisms to bring the contact senor tip onto the part being measured thus simplifying the overall gauge design. A pneumatic displacement sensor (gauge probe).

allows the number of parts in the fixture to be reduced resulting in improved reliability and reduced fixture cost. It also allows for fast automatic loading of the part into the gauge as the displacement probe tip can be in the fully ‘retract position’ when this is occurring.

VIDEO

Catalogs

Other SOLARTRON METROLOGY products

Orbit® Digital Measurement Network

Related Searches

- Micrometer

- Solartron touch probe

- Solartron measurement touch probe

- Digital micrometer

- Bore micrometer

- Inside micrometer

- Compact touch probe head

- Solartron linear measurement touch probe

- Solartron spring touch probe

- Solartron digital touch probe

- Solartron pneumatic touch probe

- Solartron digital touch probe

- Rugged touch probe head

- Analog touch probe

- Inductive touch probe

- Lever touch probe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.