Simulation software CADprogrammingEDM

Add to favorites

Compare this product

Characteristics

- Function

- process analysis, programming, simulation, CAD, design, EDM

- Applications

- process, machining, for CNC machines

- Type

- 3D

- Deployment mode

- cloud

- Other characteristics

- SolidWorks

Description

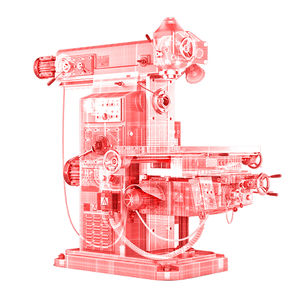

Easily create instructions for CNC machines to ensure your parts can be manufactured quickly without delays or errors

Cut Programming Time and Stay Ahead of Schedule

NC Shop Floor Programmer is a powerful role in the 3DEXPERIENCE® Works portfolio that enables NC programmers to create and validate 2.5- and 3-axis NC programs, generate wire EDM operations, and verify possible issues during production with machine simulation. You can store and access your data on the 3DEXPERIENCE platform, and quickly search for and find the part you want to fabricate, and then start working on the NC programming so it is ready for machining long before project completion.

Easy to Set Up

The Shop Floor Machining Wizard quickly guides you through setup. Just select the machine you’ll be using, machine tools you work with regularly, define your stock material, and you’re ready to go.

Powerful Simulation

Quickly identify accessibility and collision issues. Machine simulation allows programmers to detect machine axis limit errors and tool reachability problems and create simulation time charts.

In Sync

Having all your data in one place on the cloud bridges the gap not only between design and manufacturing but enables easier collaboration across the entire organization.

Time-saving Tools

NC Shop Floor Programmer delivers powerful 3D machine programming capabilities, including:

Surface Machining for generating faster and higher-quality toolpaths on the CAD model geometry vs. mesh data

Intermediate Stock so you can see how the machining operation will impact the manufacturing process

VIDEO

Catalogs

No catalogs are available for this product.

See all of SOLIDWORKS Europe‘s catalogsRelated Searches

- SOLIDWORKS automation software

- SOLIDWORKS management software

- SOLIDWORKS analysis software

- SOLIDWORKS process software

- SOLIDWORKS Windows software

- SOLIDWORKS CAD software

- SOLIDWORKS control software

- SOLIDWORKS real-time software

- SOLIDWORKS cloud software

- SOLIDWORKS design software

- SOLIDWORKS 3D software

- Monitoring software solution

- SOLIDWORKS interface software

- SOLIDWORKS industrial software

- SOLIDWORKS quality software

- SOLIDWORKS simulation software

- SOLIDWORKS visualization software

- Programming software

- SOLIDWORKS automated software

- SOLIDWORKS development software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.