- Products

- Catalogs

- News & Trends

- Exhibitions

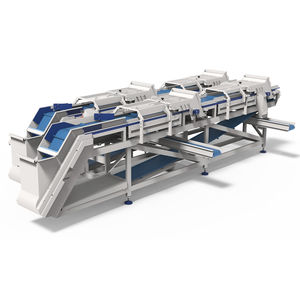

Carrot vegetable cutting machine WSS

Add to favorites

Compare this product

Characteristics

- Food product

- carrot

Description

The Sormac process cutter type WSS is constructed for cutting large quantities parallel type carrots, e.g. for manufacturing baby carrots.

The carrots are cut to a pre-determined fixed size, mostly 50 mm (2″), and all undersized pieces that are too short for further processing can be removed from the production by an additional vibratory grader or piece remover.

The machine consist of a number of stainless steel elevator trays, which are mounted on two drive belts. The carrots are elevated by these trays which are slotted at 50 mm (2″) increments to allow the free passage of rotating knives which cut through the carrots at right angles.

A rotating spiral brush takes care that the carrots are well positioned in the trays and all excessive carrots are removed.

Product specification

simple and robust construction

manufactured of stainless steel, including the trays

minimal wearing parts

Capacity

The capacity of the process cutter depends on an equal delivery over the whole width of the machine, with a practical top production rate up to 5 tons/hour (11,000 lbs/hr).

VIDEO

Related Searches

- Slicer

- Automatic slicer

- Food washing tunnel

- Vegetable food cleaning machine

- Peeling machine

- Vegetable peeling machine

- Fruit food cleaning machine

- Fruits and vegetable slicing machine

- Continuous slicing machine

- Vegetable cutting machine

- Semi-automatic slicing machine

- Fruit and vegetable cutting machine

- Potato peeling machine

- Carrot peeling machine

- Vegetable slicing machine

- Carrot vegetable cutting machine

- Onion peeling machine

- Potato vegetable cutting machine

- Coring machine

- Potato slicing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.