- Products

- Catalogs

- News & Trends

- Exhibitions

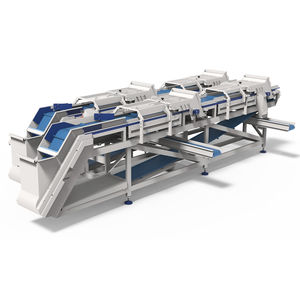

Fruits and vegetable grader DST

Add to favorites

Compare this product

Characteristics

- Applications

- for fruits and vegetables

Description

The Sormac small piece removal grading drum type DST consists of an horizontal cylinder manufactured of stainless steel which rotates around the horizontal-axle.

In the outer wall of the main drum, hollow plastic cups are mounted flush with the internal wall completely covering the whole drum. During the rotating movement of the drum the product slides over the inner wall and the small tops/tails and undersized pieces of carrot fall into the depressions within the internal section of the cups. All the product that falls into the cups and is undersize of the circular cups diameter, travels upward in the drum rotation and after a half a rotation the pieces fall out off the cups onto the internally mounted conveyor belt and are transported out of the drum. A set of special rotating brushes mounted above the drum assists the product removal by allowing the brush to penetrate into the cups ensuring a continual process of empty cups moving into the new product.

The diameter of the piece removal cups is determined by the volume of product to be graded. There are a large selection of grading cups available with openings of Ø 25 to Ø 80 mm (1,38″ – 3,15″). To achieve the correct cup size for small piece removal the diameter of the product also needs to be taken into consideration.

Small piece removal grading drums are mostly used for carrots, e.g. in baby carrot lines, after cutting the carrots or after peeling and polishing. The drum and frame are completely built of stainless steel and are executed with adjustable feet. Subject to capacities different drum diameters and lengths are available.

Related Searches

- Dynamic homogenizer

- Drying system

- Homogenizer for the food industry

- Sorting machine

- In-line dryer

- In-line mixer

- Automatic sorting machine

- Vertical centrifuge

- Laboratory centrifuge

- Drying system for the food industry

- Food washing tunnel

- Centrifugal dewatering system

- Food sorting machine

- Sorting machine for the food industry

- Vegetable food cleaning machine

- Gauging

- Top-loading centrifuge

- Floor-standing centrifuge

- Fruit food cleaning machine

- Rotary drum blender

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.