- Products

- Catalogs

- News & Trends

- Exhibitions

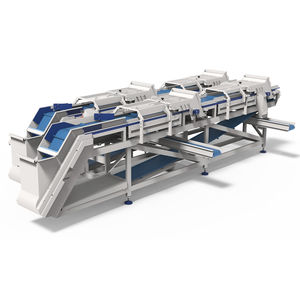

Semi-automatic sorter SRfor carrotsfor wasterotary

Add to favorites

Compare this product

Characteristics

- Operational mode

- semi-automatic

- Product applications

- for carrots, for waste

- Other characteristics

- rotary

Description

The Sormac sliver remover is manufacturered with a series of ribbed rollers with an adjustable distance between each roller. The roller bed is inclined creating an angle for optimal product transit. The produce flows crosswise over the rollers with a forward product speed dependent on the angle of the roller bed and the rotational speed of the rollers. The undersized product falls through the rollers aided by the external ribbing around the roller and the whole graded product passes forwarded.

The waste falling through the rollers, is caught in a hopper and collected in a crate or waste belt under the machine.

The distance between the rollers is adjustable between 4 and 16 mm (0,16″ – 0,63″) by placing fixed pre-sized spacers between the axles of the rollers. The machine will be supplied with 3 sets of distant spacers. Sliver removers are used for removing small misshaped pieces out off parallel shaped cut root vegetables.

The machine is completely constructed of stainless steel. The roller rotational speed is controlled by a stainless steel drive motor. The angle of the roller bed can be adjusted to suit individual product types.

Product specification

simple construction

speed, roller distance and angle of incline are fully adjustable

complete stainless steel manufacture

Capacity

The machines capacity depends of the width and the number of rollers within the machine and the tolerances required within the product specification. Capacities up to 3 tons per hour (6,600 lbs/hr) can be achieved subject to specification.

VIDEO

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Conveying belt

- Conveyor for the food industry

- Roller rail conveyor

- Sorting machine

- Inclined conveyor

- Food conveyor

- Conveyor belt for the food industry

- Automatic sorting machine

- Screw conveyor

- Weigher

- Mobile conveyor

- Conveyor system

- Food sorting machine

- Sorting machine for the food industry

- Weigher for the food industry

- Trough conveyor

- Vibrating conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.