- Products

- Catalogs

- News & Trends

- Exhibitions

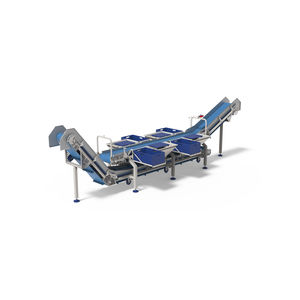

Vegetable washing machine Pulstar

Add to favorites

Compare this product

Characteristics

- Food product

- for vegetables

Description

The Pulstar washer has an integrated air injection system, enabling a thorough cleaning action without damaging the product. The quantity of air can be adjusted continuously, so that a stronger or softer turbulence in the washing water can be achieved. The air injection system is divided into two sections, which operate alternatively. This alternating operation of the sections creates a peristaltic movement of the product through the washer.

The variable water flow of the frequency driven circulation pump in combination with the air injection switch/change frequency ensures

that the product is transported through the washer and that the dwell time in the washer can be controlled accurately.

Water and product can be separated on an outfeed belt (optional) on the outfeed side. The water is passed thruogh an overflow tank and then flows to the pump tank. Loose particles are filtered out of the water using a static sieve. The outfeed belt can optionally be configured as a de-watering belt. This has one or more beaters and vacuum stations.

Several configurations are available.

VIDEO

Related Searches

- Dynamic homogenizer

- Drying system

- Homogenizer for the food industry

- Sorting machine

- In-line dryer

- In-line mixer

- Automatic sorting machine

- Vertical centrifuge

- Laboratory centrifuge

- Drying system for the food industry

- Food washing tunnel

- Centrifugal dewatering system

- Food sorting machine

- Sorting machine for the food industry

- Vegetable food cleaning machine

- Gauging

- Top-loading centrifuge

- Floor-standing centrifuge

- Fruit food cleaning machine

- Rotary drum blender

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.