- Products

- Catalogs

- News & Trends

- Exhibitions

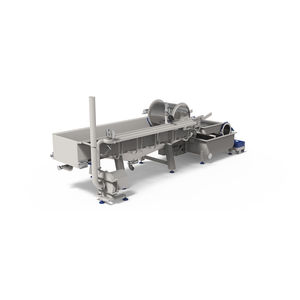

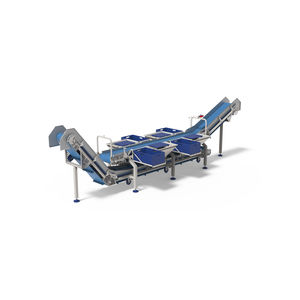

Water washing system WFfor the food industrywith conveyor

Add to favorites

Compare this product

Characteristics

- Technology

- water

- Applications

- for the food industry

- Other characteristics

- with conveyor

Description

The Sormac washing flume consists of a unique concept with a stainless steel water conveyor flume provided with an air injection system for creating turbulence in the water, thereby cleaning product in the flume. When the product is fed out from the flume, it is collected on a conveyor belt and separated from the washing water.

On a rotating sieve, coarse parts are removed from the washing water and the water then flows into the pump tank, after which the water is pumped back to the infeed side of the flume. The calm laminar flow also makes the flume excellently suitable for separating small stones, clay granules and sand particles from the product.

At the end of the flume, a sand outlet with a pneumatic outfeed valve is provided in the bottom. The design of the flume allows the desired form to be simply incorporated in different plants and in different lengths.

Optionally the flume may also be provided with multiple air injection systems.

Capacity

The washing flume is used for capacities from 300 to 3,500 kg/hour, depending on product type and dwell time.

Iceberg lettuce max. 3,500 kg/hour.

Spinach max. 2,500 kg/hour.

Baby leaf max. 2,000 kg/hour.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.