- Products

- Catalogs

- News & Trends

- Exhibitions

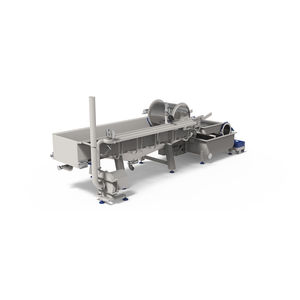

Drying tunnel for the food industry LDT-50/5D

Add to favorites

Compare this product

Characteristics

- Applications

- for the food industry

Description

The Sormac air drying tunnel was developed specifically for drying delicate leafy vegetables and for creating a low attached moisture percentage with leafy vegetables.

Before reaching the drying tunnel, the product goes through a preliminary de-watering step by means of a de-watering belt.

In the drying tunnel, the product is dried in an air stream that is oriented upwards, at a temperature of 25 to 30 ºC. The air speed is such that the product will float, causing as much moisture as possible to be released.

The air stream that is in circulation is cooled down in a heat exchanger to a temperature of approx. 5 ºC. Some of the water vapour is removed from the air stream because it condenses on the cold fins of the heat exchanger.

To enable the air to absorb moisture again, it is passed through a second heat exchanger where it is warmed up to a temperature of 25 to 30 ºC, lowering its relative humidity.

While drying the product, the air cools down due to the evaporation of the surface water on the product. This effect keeps the product much cooler than the drying air.

The air is cooled down and warmed up by using a refrigirant of approx. 0 ºC and, respectively, 33 ºC.

The air drying tunnel enables moisture values of less than 2% on the surface of the product to be reached.

The LDT-50/5D air drying tunnel is equiped with it’s own cooling installation. No additional refrigiration is required.

Product specification

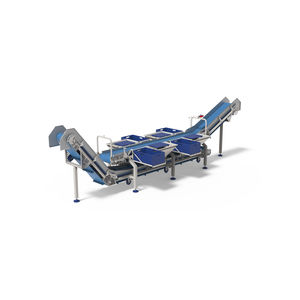

very gentle handling at volume production

suitable for delicate products

low end moisture can achievable

no energy discharge into the adjacent surroundings

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.