- Robotics - Automation - Industrial IT

- Automation

- Field monitoring system

- Sparks Instruments SA

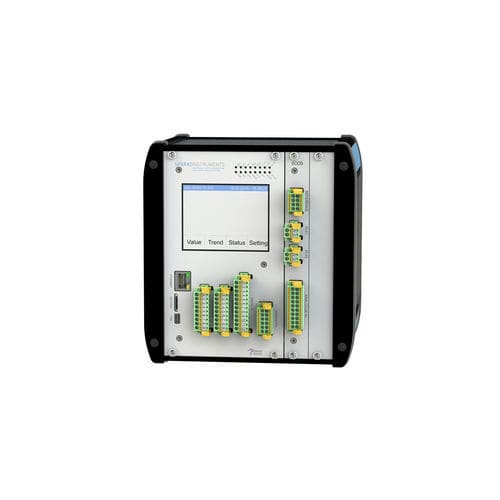

Magnetic field monitoring module UDL-M8009measurementModbusEthernet

Add to favorites

Compare this product

Characteristics

- Type

- magnetic field

- Applications

- measurement

- Interface

- Modbus, Ethernet

- Other characteristics

- continuous

Description

The UDL-M8009 Magnetic Flux Monitor monitors the presence of rotor flux abnormalities that are caused by the deterioration of the rotor winding.

Operational stresses caused by fluctuating load balances expedite the deterioration of rotor winding insulation in aging machines. Manufacturing and installation defects can also damage the rotor winding in new machines.

The UDL-M8009 Magnetic Flux Monitor is a simple, cost effective, powerful tool that delivers the following benefits:

• Unnecessary expensive and logistically complicated machine re-balancing can be avoided by first identifying if a fault is due to an electrical imbalance as apposed to a mechanical imbalance.

• Safely and confidently delay scheduled rotor winding maintenance based on reliable monitoring data.

• Protects you during the site acceptance phase of new, or recently serviced generators where manufacturing and installation defects that result in damaged rotor winding can be quickly identified prior to accepting the machine.

• Continuous High Speed Acquisition of Rotor Flux Profile

• Ethernet and Modbus RTU Interfaces

• Standalone Operation

• Local True Color Touch LCD

• Flux Sensor Input Sampling Rate: 100kS/s A/D Resolution: 16 bit Input Impedance: 100kOhm, Differential No. of Sensor Interfaces: 2

• Reference Channel 1 Input Range: 0 .. 300VAC Frequency Range: DC .. 100Hz Galvanical Insulated: 2500VAC Input Impedance: 10M Ohm

• Reference Channel 2 Input Range: +/-30V Frequency Range: DC .. 10kHz Input: Differential Input Impedance: 100 kOhm

• Operation Parameters No of Channels: 5 Input Range: 4-20mA

• Input: Single Ended Measurement Shunt: 250 Ohm

Catalogs

No catalogs are available for this product.

See all of Sparks Instruments SA‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.