- Metrology - Laboratory

- Analytical Instrumentation

- Oil sampler

- Spectro Scientific

- Products

- Catalogs

- News & Trends

- Exhibitions

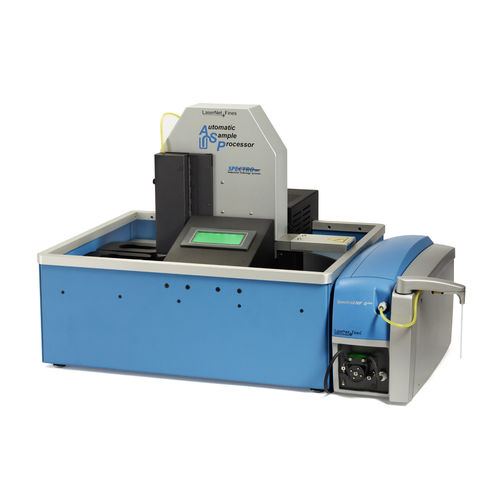

Liquid sampler ASPparticleoilautomatic

Add to favorites

Compare this product

Characteristics

- Sample type

- liquid, particle, oil

- Technology

- automatic

- Other characteristics

- benchtop

Description

Application: Machine Condition Monitoring

The ASP is a self-contained sample changer and processor designed specifically for use with the LaserNet 200 series instruments. It provides the user with automatic and unattended processing of 24 oil or hydraulic fluid samples.

The ASP features a reversing paddle that stirs each sample to provide a homogeneous particle distribution. While the LaserNet 200 series instruments analyzes a sample, the ASP stirs the next one. A peristaltic pump draws the sample through the sipper of the ASP to the LaserNet. After processing, a robot elevates the sample sipper and sample stirrer from their respective sample bottles and lowers them into spray chambers for cleaning. Rinse solvent, interspersed with air pulses, is also pumped through the sipper tubing and the LaserNet 200 flow cell to wash away traces of the previous sample. The procedure is repeated until up to 24 samples are analyzed and processed. Sensors monitor the complete process, step by step.

Analytical Test

Automation for LaserNet 200 series particle counter

Automatic/unattended sample analysis

No sample preparation

Automatic re-suspension of settled particles

Maximum sample throughput; processing time depends on sample characteristics

Low solvent consumption, use inexpensive solvent (odorless kerosene or Electron Solvent)/

Low operating cost per sample

Specifically designed for the LaserNet 200 series

Two-stage wash system uses focused spray jets

Works with standard, readily available sample bottles

Catalogs

LaserNet 200 Series

4 Pages

Related Searches

- Concentration analyser

- Monitoring analyser

- Liquids analyser

- Desktop analyzer

- Automated analyzer

- Dust analyzer

- Spectrometer

- Portable analyser

- Continuous analyser

- Water analyser

- Compact analyser

- Laboratory analyser

- Automatic test equipment

- Digital analyser

- NDIR analyzer

- Power quality analyzer

- Sampling analyser

- Lab spectrometer

- Portable test kit

- Compact spectrometer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.