Solid pin self-clinching

Add to favorites

Compare this product

Characteristics

- Type

- solid

- Specifications

- self-clinching

Description

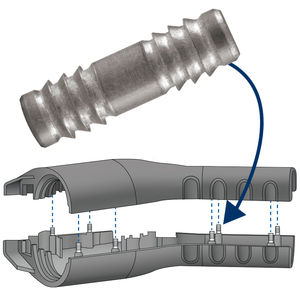

Solid Pins are straight, cylindrical, relatively inflexible press-fit pins. Solid Pins are commonly used to locate components in a fixed position, to maintain alignment, or to act as axles, pivots or hinges.

SPIROL’s Knurled Pins and Barbed Pins have raised “ridges” that interact with the host material to retain the pin within the hole. SPIROL’s Press-N-Lok™ Pin has opposing barbs on each end of the pin and is designed to permanently retain two plastic components to each other. Unlike Straight Pins and Ground Dowels that require extremely tight hole tolerances, SPIROL’s Knurled Pins are designed to be used in standard drilled holes to minimise manufacturing costs. Using this approach, SPIROL’s Solid Pins are commonly used to replace expensive machined pins. Cumbersome screws are often replaced with Knurled Pins and Barbed Pins that offer better retention and improved assembly speeds.

SPIROL minimises cost through standardization of raw material, tooling concepts and production methodology, and investment in state-of-the-art cold heading and secondary processing technology. Our internal production processes are controlled by continuous inprocess monitors and are certified to international standards IATF 16949.

If installation equipment is required, SPIROL also offers a standard comprehensive line of Pin Installation Equipment from manual to fully automatic modules, with or without out fixturing, to support your Solid Pin assembly requirements

Application Engineering Assistance: If you would like assistance in selecting the proper Solid Pin - including the recommended hole size, tolerance and installation method - please Request Engineering Support! We are here to help!

Catalogs

SPIROL Solid Pins Catalog

12 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- SPIROL threaded insert

- SPIROL metal insert

- SPIROL round insert

- Metal washer

- SPIROL pin

- Round washer

- Nickel-plated brass insert

- SPIROL metal pin

- Steel washer

- SPIROL plastic insert

- Aluminum insert

- Press-in insert

- Steel pin

- Flat washer

- Self-tapping insert

- Knurled insert

- Stainless steel pin

- Hexagon locknut

- Molded-in insert

- Chock

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.