- Products

- Spray system

- Spraying Systems Co.

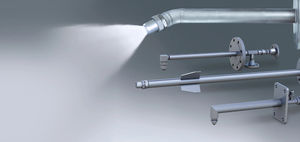

Spray system PanelSpray® series

Add to favorites

Compare this product

Description

Precise Spray Application for Engineered Wood Products

PanelSpray Systems can help overcome a variety of problems related to the over- and under-application of materials used in engineered wood production. These systems are ideal for manufacturing OSB, MDF, plywood, particleboard and other products. They allow for:

*Precision Spray Control to ensure accurate application with minimal waste, even when tonnage varies or line speed changes.

*Reduced use of costly resins, waxes and release agents by applying only the volume needed.

*Increased production by applying the optimal amount of surface moisture to decrease time in the press

*Protection from presses sticking when making the transition to running full MDI products.

*Elimination of compressed air usage for most wax and pre-press operations.

Five system options are available to ensure proper volume of fluid delivered to chips, mats, cauls or belts:

*PanelSpray-RS for PMDI or LPF resin application in the blender.

*PanelSpray-WX for slack wax, tallow wax or e-wax application in the blender.

*PanelSpray-MS for surface moisture addition prior to pressing boards.

*PanelSpray-RA for mixed release agent application on mats, cauls or press belts when using PMDI resins.

*PanelSpray-NM for nail line marking on OS.

Catalogs

No catalogs are available for this product.

See all of Spraying Systems Co.‘s catalogsOther Spraying Systems Co. products

Application-Specific Automated Spray systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.