- Power Transmission - Mechanical components

- Mechanical Transmission

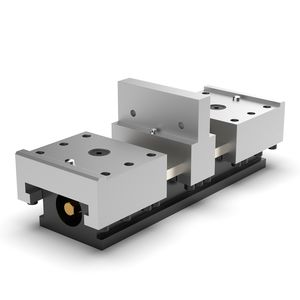

- Mechanical clamping unit

- Spreitzer GmbH & Co. KG - Präzisionswerkzeuge

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Mechanical clamping unit RS machiningworkpiecesteel

Add to favorites

Compare this product

Characteristics

- Type

- mechanical

- Applications

- machining, workpiece

- Other characteristics

- steel

Description

Mechanical raw parts clamping units are used on 5- and multi-axis machines.

You get a maximum degree of liberty due to the small dimension in combination with palletizing systems.

A maximum clamping force is attained by the back cut in the fix jaw and the clamping jaw.

An additional slot stone can be used for axial positioning.

Form cutters to prepare workpieces are available on request.

Working steps:

1. Sawing raw material

2. Machining dovetail contour

3. Clamping raw material

Advantages at a glance

Small disturbance range

Maximum access

Material: steel

Finish: hardened, black-finished

Only 3 – 5 mm clamping depth necessary

Clamping from outside to inside (external clamping)

Pairing accuracy 0,02 mm

Explanation type: model length (mm)

Type: RS 60, RS 100.

Please specify the type when raising a request.

Catalogs

Other Spreitzer GmbH & Co. KG - Präzisionswerkzeuge products

Stationary workholding

Related Searches

- Clamp

- Workholding component

- Hydraulic clamping device

- Mechanical workholding component

- Clamping fixture

- Mechanical clamping system

- Workpiece workholding component

- Workpiece clamping system

- Mechanical clamping fixture

- Machining clamping fixture

- Workpiece clamping fixture

- Modular clamping system

- Clamping set

- Mechanical clamping set

- Pneumatic clamping fixture

- Steel clamping system

- Steel clamping fixture

- Multiple clamping system

- Quick clamping system

- Swing clamping element

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.