- Machine-tools

- Machine Tool Accessory

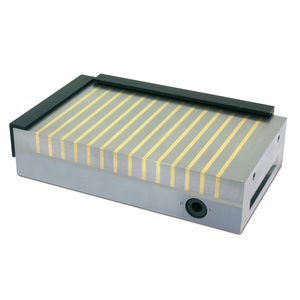

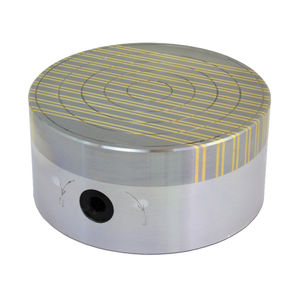

- Electro-permanent magnetic chuck

- Spreitzer GmbH & Co. KG - Präzisionswerkzeuge

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

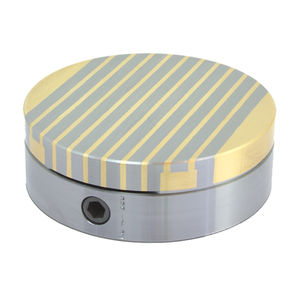

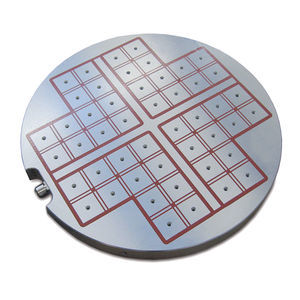

Electro-permanent magnetic chuck SPPFR roundfor grindingfor turning

Add to favorites

Compare this product

Characteristics

- Technology

- electro-permanent

- Type

- round

- Applications

- for grinding, for turning

Description

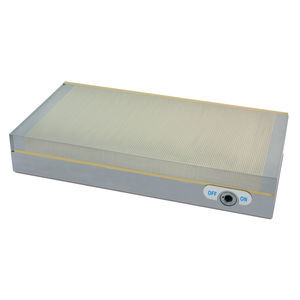

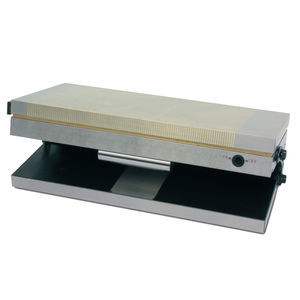

SPPFR magnetic chucks are used for the final machining of rings and for hard turning or grinding. The strengthened ceramic magnetic system also allows to demagnetize high-alloyed and hardened materials after processing.

The monoblock-body and the brass insulated magnetic poles enable maximum rigidity and excellent heat dissipation. Optionally deployable mobile and flexible pole extensions, allow to clamp the workpiece without deformation. Diameters up to 2000 mm can be manufactured on the base body of the magnetic chuck. For larger diameters individual segments can be attached to increase the clamping area. The cable connection of the pole-reversal control unit can be plugged in at the side or connected via slip ring contact on the back.

Catalogs

Magnetic clamping

64 Pages

Other Spreitzer GmbH & Co. KG - Präzisionswerkzeuge products

Magnetic clamping technology

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.