- Products

- Catalogs

- News & Trends

- Exhibitions

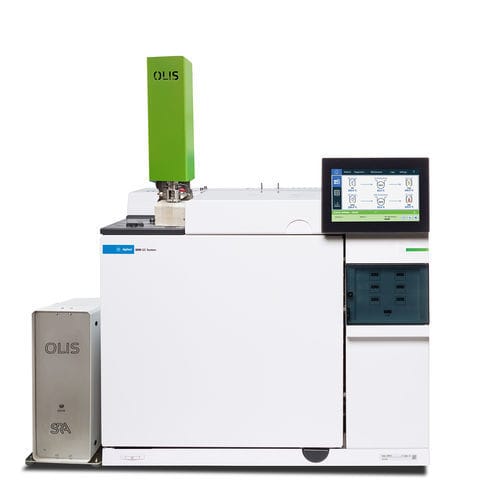

Gas injection controller OLIS

Add to favorites

Compare this product

Description

The injection system OLIS (On-line Liquid Injection System) is specially designed for the injection, in gas chromatography, of liquid matrixes up to a pressure of 60 bar. The advantage of this injector is its ability to work on-line, under pressure and without discrimination, unlike conventional injection systems.

Based on a simple operating principle: an actuator or stem is driven by a micro-electric motor from its upper position (filling stage) to its lower position (injection stage). This stem has a constant sampling volume of several hundred nanoliters and the liquid it contains is instantly vaporized by flash heating during injection. The OLIS valve is particularly suited for the analysis of liquid samples with a wide range of boiling points, viscous or with high polarity.

Advantages :

Stand-alone and easy to use system

Analysis of unstable liquid samples to be characterized

Very little discrimination between compounds

Adaptable to a new GC or an existing one

Maintenance: low maintenance and easy to carry out by the user

Better reproducibility than automatic injection with a syringe

Characteristics :

Stem with a machined end to allow sample circulation

Continuous or syringe-pushed sample circulation

Instantaneous vaporization by flash heating of the liquid fraction contained in the calibrated volume

Electronic interface with on-board intelligence integrating numerous control points (stem temperature, stem position at injection, etc…)

Application fields :

LPG, LNG, naphtha, condensate

ASTM D-2887

Alcohols in hydrocarbons

BTEX

CO2 dissolved

Impurities in amino matrix

Catalogs

No catalogs are available for this product.

See all of SRA‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Hyvolution 2025

28-30 Jan 2025 paris (France) Stand 6G66

Related Searches

- Nitrogen gas generator

- PSA nitrogen gas generator

- Laboratory nitrogen gas generator

- Hydrogen gas generator

- Membrane nitrogen gas generator

- Laboratory hydrogen gas generator

- UHP nitrogen generator

- Pure hydrogen gas generator

- Compact hydrogen gas generator

- Process hydrogen gas generator

- High-pressure nitrogen gas generator

- High-pressure hydrogen gas generator

- Gas injection controller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.