- Metrology - Laboratory

- Analytical Instrumentation

- Sulfur analyzer

- SRI Instruments

Gas analyzer 8610-0073sulfurcompactgas chromatography based

Add to favorites

Compare this product

Characteristics

- Measured entity

- gas, sulfur

- Configuration

- compact

- Technology

- gas chromatography based

Description

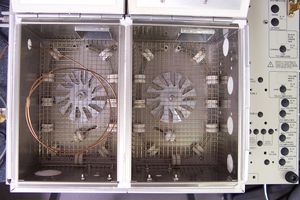

Multiple Gas Analyzer + Sulfur GCs

Detect low sulfur concentrations

Multiple gas analysis AND sulfur analysis in one unit

Uses just 1 gas sampling valve and 3 columns

Built-in, "whisper quiet" air compressor

6 channel PeakSimple data system on the compact 8610C chassis, or on the 8610V chassis for just $2,100 more.

The inert sample loop is visible on the front of the valve oven.

Many analysts require natural gas analysis for various applications. Frequently, sulfur compounds are also of interest.

Because low sulfur concentrations (<50 ppm) are difficult to measure, SRI has enhanced our popular Multiple Gas Analyzer GC systems to simultaneously monitor low levels of sulfur compounds. The additional hardware required is an FPD/FID detector, which selectively detects sulfur down to mid-ppb range, and a room temperature sulfur-inert sample loop.

One reason sulfur is so difficult to measure is that it disappears on contact with hot stainless steel surfaces; even limited contact with a hot stainless steel loop will destroy any sulfur in the gas sample. Our solution is to use an inert transfer line leading to a splitter, and a 60-meter thick film capillary column. While Teflon columns are sometimes also used for sulfur analysis, the natural gas analysis (using molecular sieve and HayeSep D) requires column temperatures of 250°C or higher. Since the sulfur column is located in the column oven, it is essential to use a column like the 60-meter capillary which can tolerate the higher temperatures.

Catalogs

No catalogs are available for this product.

See all of SRI Instruments‘s catalogsRelated Searches

- Gas analyser

- Liquids analyser

- Desktop analyzer

- Dust analyzer

- Gas detector

- Integration analyser

- Water analyser

- Compact analyser

- Laboratory analyser

- In-line analyser

- Compact detector

- CO detector

- Chromatography system

- CO analyzer

- O2 detector

- Laboratory chromatography system

- Rugged detector

- CH4 analyzer

- H2S detector

- CH4 detector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.