Conductor-filled seal toroidalflatwith circular cross section

Add to favorites

Compare this product

Characteristics

- Type

- toroidal, flat

- Configuration

- with circular cross section, round, U-shaped, profiled, V, grooved, rectangular, C, tubular, D-shaped

- Material

- elastomeric, EPDM, silicone

- Application

- fitting, housing, industrial, for aircraft, for connectors, electronic equipment, flange, industry, door, for high-temperature applications, for electronic applications, for actuators, EMI shielding, for medical equipment, for railway vehicles, for aerospace applications, for medical applications, military, for specific applications, for electronic components

- Other characteristics

- chemical-resistant, static, high-temperature, custom, molded, extruded, conductor-filled, waterproof, self-adhesive, flat, one-part

- Temperature limit

Min.: -55 °C

(-67 °F)Max.: 200 °C

(392 °F)

Description

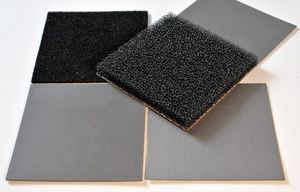

CONDUCTIVE ELASTOMER EMI

This material is made with silicone filled with conductive particles (Carbon, Nickel Graphite, Silver Aluminum, Silver Copper, Silver pure). It provides excellent shielding against electromagnetic interference EMI RFI, and also seals the equipment. The nature of these fillers also allows them to act as a very good thermal conductor. A fluorinated version is also available in order to withstand contacts with hydrocarbons, oils and solvents. These elastomers are available in cut, extruded profiles, and moulded shaped plates.

BI-MATERIAL ELASTOMER

The bi-material seal consists of an elastomer side filled with conductive particles and a silicone or fluorosilicone side. Its purpose is to isolate the conductive part of the corrosive environment (humidity, salt fog). It can also be manufactured in different grades of hardness as required. It can be co-extruded or moulded.

In contrast to an extruded gasket, a shaped seal can be installed very quickly.

In order to expand the field of use of these gaskets, STACEM has developed a moulding combination, of a filled silicone to an EPDM (resistance to Skydrol) or a fluorocarbon (resistant to NRBC).

The manufacturing method that has been developed offers a high chemical bond between the two materials.

Several grades of elastomers are possible, enabling the use in many applications (aircraft, military, nuclear, medical, food, chemical, ...).

Catalogs

No catalogs are available for this product.

See all of STACEM‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.