- Products

- Torque verification tool

- STAHLWILLE EDUARD WILLE GmbH & Co. KG

Torque verification tool SENSOTORK® 7707-2W series

Add to favorites

Compare this product

Description

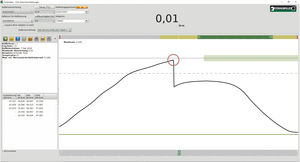

Electronic workshop tester for checking and adjusting indicating and triggering torque wrenches.

Simple, quick and reliable testing of torque wrenches to ensure quality in production.

Measurement in the large torque range up to 1.100 N·m.

Simple exchange of transducers enables quick adjustment to different measuring tasks and specific testing requirements.

The interchangeable square adapters in the mounting block allow flexible use with standard square drive sizes.

Properties

for testing indicating and triggering torque screwdrivers

compact electronic testing device consisting of:

1 patented transducer

1 safety lock

1 display device (DBGM)

1 stand with 1.5 metre cable for the display unit

1 spiral cable

1 power supply (110 V-230 with interchangeable plug adapters)

4 interchangeable square drive adapters for the square drive

large LCD display for optimum readability

horizontal or vertical installations

for controlled right and left measuring

3 operating modes: running display of the applied torque (Track), display of the torque on triggering/kink point detection (First-Peak), peak value display (Peak-Hold)

additional control from the display of the actual tightened torque on triggering torque wrenches

with QuickRelease security lock

low transverse forces due to flat transducers

automatic detection of transducers

Catalogs

No catalogs are available for this product.

See all of STAHLWILLE EDUARD WILLE GmbH & Co. KG‘s catalogsOther STAHLWILLE EDUARD WILLE GmbH & Co. KG products

Torque tools

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.