- Production Machines

- Textile machinery

- Staubli Textile

- Products

- Catalogs

- News & Trends

- Exhibitions

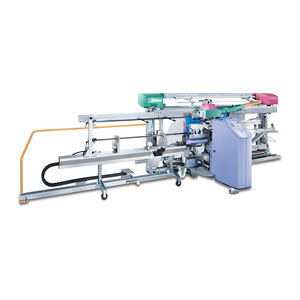

Reading-in machine BEAMPRO

Add to favorites

Compare this product

Description

As a leading global provider of automation solutions for warp preparation, Stäubli constantly focuses its research-and-development efforts to achieve one goal: to bring substantial benefits to weaving mills and make every process related to weaving preparation more efficient.

With its recent innovation, the BEAMPRO reading-in machine, Stäubli has tackled the process of sizing and added a highly efficient element for optimization within the overall process of warp preparation.

From the colored beam dyed sizing process to a completely drawn-in weaving harness – in just two process steps

In the multi-color weaving mill, when warps are produced by combining various single-colored sectional warp beams, they are typically assembled directly on the sizing machine. In this case, achieving the highest fabric quality requires exact yarn order, precise color repeat, and homogeneous warp structure. This is where BEAMPRO comes into play: Using BEAMPRO on the sizing machine, the warp can – even without a 1:1 lease – immediately afterwards be swiftly drawn in on a SAFIR automatic drawing-in machine featuring the AWC option Yarn Repeat Management, resulting in a high-quality, ready-to-weave weaving harness including warp beam in one set.

Automation of the reading-in process at the comb instead of labour-intensive manual sorting of yarns

Precise yarn order in the comb and in the warp and fewer crossed yarns

Better operating behaviour of the warp in the weaving machine and fewer broken warp yarns

Perfect execution of the colour repeat, with no need for monitoring by operating personnel

Drastic reduction of idle time of the sizing machine

VIDEO

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.