- Power Transmission - Mechanical components

- Bearing and Linear Guide

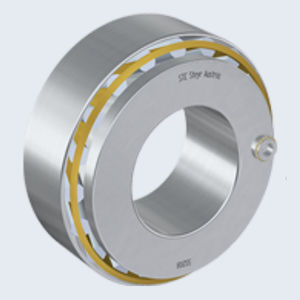

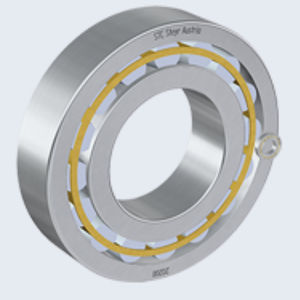

- Roller bearing

- STC-Steyr Wälzlager Deutschland GmbH

Roller bearing 2 seriesradialaxialspherical

Add to favorites

Compare this product

Characteristics

- Rolling element

- roller

- Configuration

- radial, axial, spherical

- Material

- steel, brass

- Applications

- for rolling mills

- Other characteristics

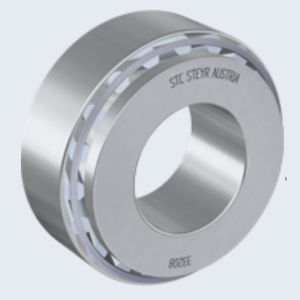

- with plastic cage, self-aligning

- Inside diameter

Max.: 1,000 mm

(39.37 in)Min.: 25 mm

(0.98 in)- Outside diameter

Max.: 1,580 mm

(62.2 in)Min.: 62 mm

(2.44 in)- Width

Max.: 580 mm

(22.835 in)Min.: 17 mm

(0.669 in)

Description

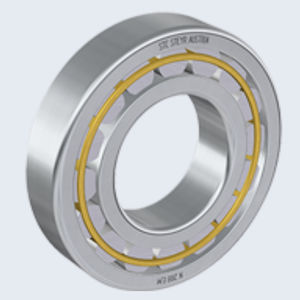

Roller bearings are bearings in which two components that move relative to each other – the so-called inner ring and outer ring – are separated by rolling elements.

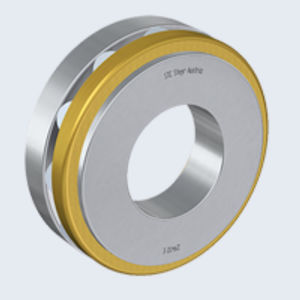

Spherical roller bearings

Spherical roller bearings have a spherical outer ring raceway and are therefore self-aligning. They can absorb high radial forces and high axial forces. As standard, there is an annular groove with three lubrication holes in the outer ring.

STC-Steyr® supplies standard spherical roller bearings with a solid brass cage or steel cage . Spherical roller bearings with plastic cage are available on request.

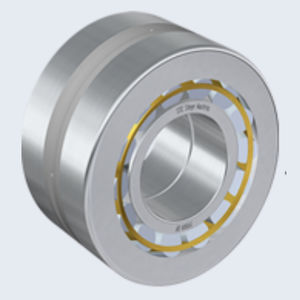

For highly alternating loads, such as those in vibrating screens and tunnel-boring machines, STC Steyr® supplies spherical roller bearings with a split cage. These are produced for rolling mills, cable sheaves, marine gear units, rudder bearings, crushing machines, hammer mills, screw conveyors, roller conveyors and vibrating screens.

Catalogs

Catalogue

250 Pages

Other STC-Steyr Wälzlager Deutschland GmbH products

ROLLER BEARINGS

Related Searches

- Rolling bearing

- Steel bearing

- Ball bearing bearing

- Roller bearing

- Radial rolling bearing

- Axial rolling bearing

- Single-row bearing

- Deep groove ball bearing

- Double-row bearing

- Precision bearing

- Cylindrical roller rolling bearing

- Cage assembly bearing

- Tapered roller bearing

- Angular-contact bearing

- High-speed bearing

- Sealed bearing

- Machine bearing

- Thrust bearings

- Spherical bearing

- Combined bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.