- Products

- Surface inspection optical system

- Steinbichler Optotechnik

Surface inspection optical system ABISoptimizer

Add to favorites

Compare this product

Characteristics

- Options

- surface inspection

Description

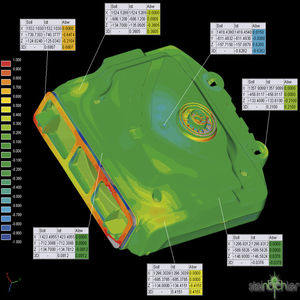

OBJECTIVE AND HIGHLY PRECISE SURFACE INSPECTION

Particularly in consumer goods industry, the surface quality of a product is a decisive criteria for purchase decisions. Furthermore, the constantly increasing competition and focus on cost control demands a timely and objective detection of surface defects during the complete product development and production cycles. The flexible, compact and highly precise ABISoptimizer sensor system has been developed especially for applications at an early stage of manufacturing processes. Practice-oriented properties such as extremely rugged design and dust-proof optical components, allows operation even under the most harsh industrial environment conditions.

EASY OPERATION AND EXCELLENT MOBILITY

Thanks to its extremely compact components, the STEINBICHLER ABISoptimizer system is ready to run with minimum preparation. The high mobility supports an easy and flexible relocation of the measurement set-up to allow in-process, selective inspections in different areas such as tool making, pilot production and also during the complete tool optimization process. Measurements are carried out simply and reliably via the userfriendly software. The user can choose from a wide range of evaluation and protocol functions which optimally support application-specific analyses.

Catalogs

ABISoptimizer

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.