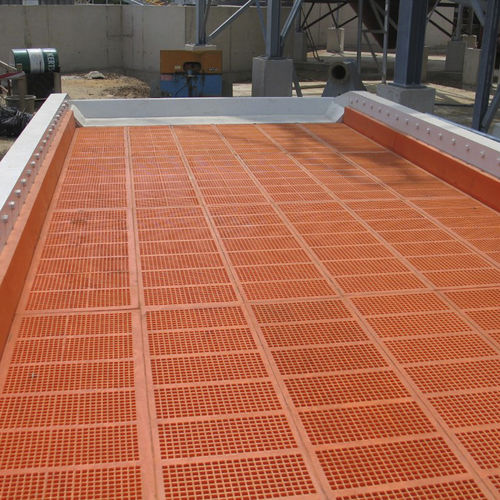

UNI 2000 modular screens

UNI 2000 – Our All-Rounder

The UNIversal all-rounder with plenty of options.

Our UNI2000 system dispenses with pin fixings and attaches the screens to the support structure using a tongue-and-groove connection, preventing vibration.

This design makes it our all-rounder. Larger open screen area, optimal side fastening. Find out more about the benefits and options.

Assembly & support structure

Attachment is easy with our tried and tested tongue-and-groove connector system. The polyurethane adapter strip protects the longitudinal bar against wear and forms the groove to receive the screen components. The screen components have the appropriate tongue, likewise of polyurethane, cast onto them. It takes very little effort to insert the screens into the adapter strips and so prevent them from vibrating.

Side fastening / Side wear guard

This is best achieved by the use of our side wear guard strip with its Jordahl profile and adapter:

The screen panel can be fitted and demounted without demounting the sidebar.

Screened material cannot be conveyed over the front end and damage the screening machine.

The sidebar cannot become detached from the side wall, thus damage is prevented.

The Jordahl profile enables the side strip bolt connections to be individually positioned.

No support and wedge brackets are required on the screening machine.

Side fastening using wedge strips and wedges is possible.

Side wear guard strips can be provided with dewatering holes.