Screening mesh TRIA® TRIAPLAST® SERPENTIwovenstainless steelsteel

Add to favorites

Compare this product

Characteristics

- Options

- screening, woven

- Material

- stainless steel, steel

Description

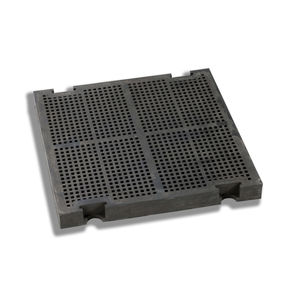

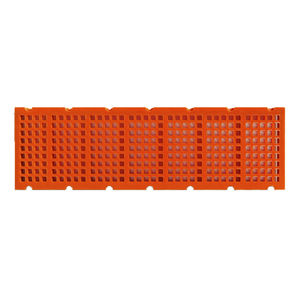

Mesh-like screen panels

Fields of application:

Because of their good self-cleaning effect, these fabric-like screen panels are successfully used:

in the stone and quarry industry,

in ore preparation,

in the mining industry

for ores, pellets, sinter, raw coal, washed coal, coke, gravel, grit, sand and gravel, limestone, cement clinker, etc.

TRIAPLAST with elastic polyurethane cross-connections further improves the self-cleaning effect. The good wear-resistance of the polyurethane lengthens the overall service life of the screen panel. Polyurethane cross-connections can be used with screened material temperatures up to a maximum of 80 °C.

TRIA and SERPENTI screen panels with cross-connections made from steel wires or polyurethane are only to be used as tension screen fields on screening machines with a tensioning device.

TRIA® harp-mesh screens

Screen panels made from alternate straight and horizontal corrugated round wires with interwoven cross-connections from round wire with 3 x 3 = 9 cross wires per layer.

TRIAPLAST® harp-mesh screens

Screen panels made from alternate straight and horizontal corrugated round wires with elastic cross-connections from highly wear-resistant polyurethane.

SERPENTI harp-mesh screens

Screen panels made from horizontal corrugated round wires with interwoven cross-connections made from round wire with 4 x 2 = 8 cross wires per layer.

SERPENTIPLAST

As with TRIAPLAST we can, if required, equip our SERPENTI screen panels with polyurethane cross-connections instead of steel cross-connections.

Screen panel attachments

Cross-connection pitches for tension screen fields

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.