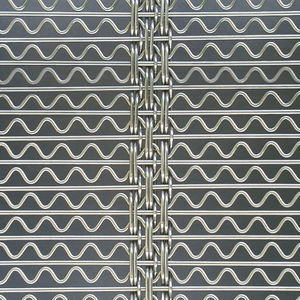

Screening mesh SOLIDAsteel

Add to favorites

Compare this product

Characteristics

- Options

- screening

- Material

- steel

Description

SOLIDA welded wedge wire screen

SOLIDA welded wedge wire screens are pressure-welded screen grids made of round wires for the particle separation of highly abrasive material to be screened, with mesh holes of 10 to 200 mm. They are vibration-proof and have large, open screen areas and a long service life.

SOLIDA welded wedge wire screens are normally manufactured and supplied with square screening apertures. However, we can also produce customised items with a long mesh grid, a large open screen area and a higher throughput rate with slightly less precise separation.

The screen panel material is a highly wear-resistant special steel with 500 to 600 N/mm² tensile strength. We also supply SOLIDA screen panels in corrosion-resistant and heat-resistant stainless steels. The exceptional welding penetration depth ensures a firm mesh bond up until the screen panel reaches the end of its service life.

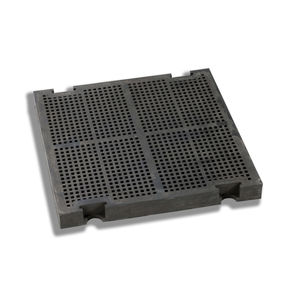

The normally flat screen fields are attached to the screening machine by screws, wedges or clamping devices. We also supply screen grids with tensioning devices, although the thick wires are not actually tensioned. The screen panel is pressed down. We recommend additional central attachment.

The screen field size is to be determined so as to ensure easy handling during transport and assembly. The overall screen surface should, if possible, be divided into screen fields of equal size so that they can be exchanged with one another in case of differing degrees of wear. We produce pressure-welded screen grids up to 1100 x 4000 mm in size, but we recommend to select screen fields with a side length of no more than 1000 mm.

Catalogs

No catalogs are available for this product.

See all of Steinhaus‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.