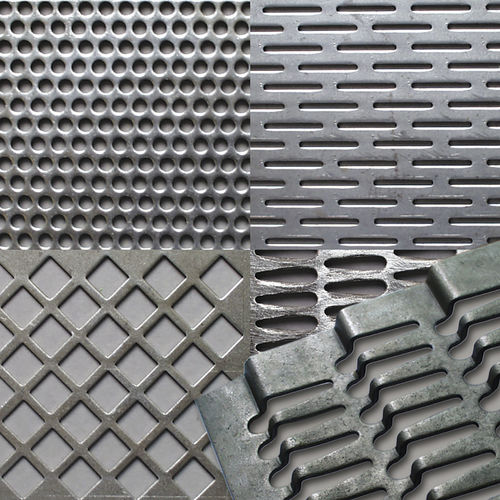

CONIDUR® perforated sheets are sheets with a special hole shape.

In contrast to the usual round hole shape with even hole sides in the through-pass direction, the perforations in the CONIDUR® perforated sheets are formed in a more triangular to half-elliptical shape, which means that they have conical openings placed at an angle in the through-pass direction.

The upper and lower side of the CONIDUR® perforated sheets differ in design.

Depending on the design of the perforation, one side (normally the side facing the product) is scaly and raw, with the other side being smooth.

The special manufacturing process enables the finest perforations in starting material sheets whose thickness may be a multiple of the hole width.

CONIDUR® perforated sheets are cold-worked during manufacture. This makes them very wear-resistant, a feature that can be further improved with the appropriate aftertreatment.

Depending on the specification, CONIDUR® perforated sheets can be processed into moulded products.