Solid filter wire meshfor pipeconical

Add to favorites

Compare this product

Characteristics

- Designed for

- for solids

- Filtration element

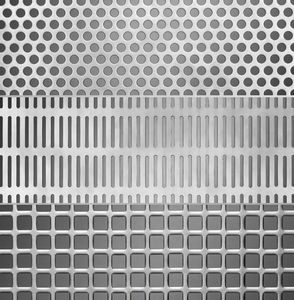

- wire mesh

- Applications

- for pipe

- Other characteristics

- conical

Description

Start-up filters / hat-type screens

During the initial commissioning of an installation, start-up filters serve to remove production residues in the pipeline and apparatus construction, such as slags and electrode residues that have found their way into the system during assembly and welding work. Damage to downstream components is thus prevented and the risk of costly operational disruptions markedly reduced.

Start-up filters comprise a support element made from perforated sheet or wire mesh, onto which the actual fine mesh filter cloth is fitted, plus a flanged ring for attaching in the pipeline. The size of the mesh holes in the filter mesh depends on the requirements.

All commonly obtainable steel qualities are used as materials for filter cloths, support elements and flanged rings.

Dual-cone start-up filters (double hat-type screen)

If the fitting length available is insufficient to accommodate a single-cone start-up filter with the required filter surface, it is usually possible to fit a dual-cone start-up filter with a reduced construction height and the same filter surface.

Catalogs

No catalogs are available for this product.

See all of Steinhaus‘s catalogsRelated Searches

- Liquid separator filter

- Filter cartridge

- Solid classifier

- Industrial filter cartridge

- Stainless steel separator filter

- Filter element

- Basket separator filter

- Gravity classifier

- Gas filter element

- Separation filter

- Separator filter for the food industry

- Filter for chemical applications

- Air filter element

- Wire mesh pre-filter

- Metal filter cartridge

- Wastewater treatment filter

- Centrifugal separator filter

- Pump separator filter

- Cylindrical separator filter

- Dust filter element

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.