- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

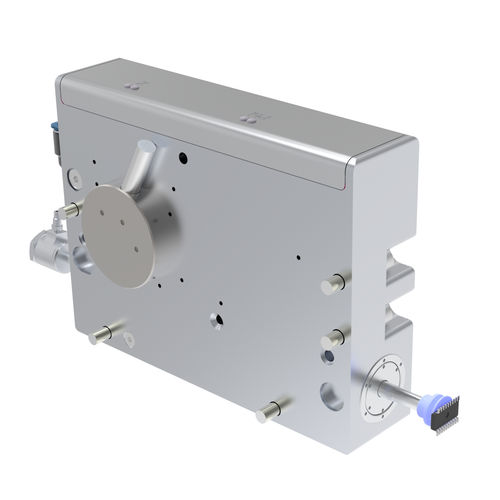

1-axis positioning system 786008:002.26linearautomaticfor laboratory applications

Add to favorites

Compare this product

Characteristics

- Number of axes

- 1-axis

- Features

- linear, automatic

- Applications

- for laboratory applications, for clean rooms, for the pharmaceutical industry

- Other characteristics

- compact, precision, linear motor-driven, with stepper motor, belt-driven

- Repeatability

10 µm

- Load

830 g

(29.28 oz)- Stroke

14 mm

(0.55 in)- Speed

Max.: 5,538 mm/s

Min.: 500 mm/s

Description

Z-Phi Rotary Stroke Actuator with integrated controller (clean room ISO 8)

Customizable:

• Ideal for automated cleanroom production e.g. adjusting, screwing in, stacking, filling and closing

• Synchronized or independent linear and rotary motions up to 14 mm x 360° (travel ranges extendable)

• Easy to expand by integrating more than 64 actuators to one bus system

• Continuous control of the entire motion for repeatabilities up to 0.03

• Long lifetime with additional fast maintenance by plug and play capability

With this Z-Phi Positioner, precise linear and rotary movements can be combined in a highly compact way. The motion can be programmed either synchronously with each other or completely independently. The motion controller with field bus interface is plug-and-play ready and is integrated directly in the positioning unit.

Specifications:

- Travel: 14 mm (Z) / n x 360 (Rz)

- Repeatability: 7 – 10 µm (Z) / - 0.03° - 0.05° (Rz)

- Positoning speed: 500 – 1000 mm/s (Z) / 2769 – 5538 mm/s (Rz)

- Max. load: 8.3 N

- Motor: Iron Core Dynamic Linear Motor (Z) / Stepper Motor, Belt (Rz)

- Feedback: Inductive Sensor

- Length x width x height: 218 x 42 x 106 m

Customized options:

- Customized software and electronic modules e.g. self-diagnosis, remote maintenance, error compensation

- Modular combination with further linear, leveling or rotary tables e.g. DT240

- Individual system configuration, vibration isolation, enclosure, safety concept

- Versions for clean room ISO 14644-1 (up to class 1 on request)

- Design for force-controlled operation

- Individual solution development with 3D Design for the positioning task

Catalogs

No catalogs are available for this product.

See all of Steinmeyer Holding GmbH‘s catalogsOther Steinmeyer Holding GmbH products

Compact Multi Axis Stages: Translation Stages, Aligner, Tripods, Hexapod Alternative

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.