- Machine-tools

- Machine Tool Accessory

- Universal measuring gauge

- Steinmeyer, Inc.

Universal measuring gauge 782492:001.26

Add to favorites

Compare this product

Characteristics

- Options

- universal

Description

Circular Measuring Gauge for concentricity, circularity and cylindricity | measuring range: max. length 400 mm / Ø 35 mm

Universal circularity measurement of cylindrical objects

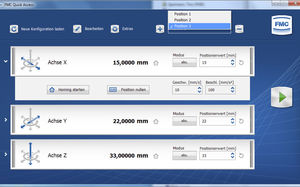

The force asserted by gravity is disturbing during measurement of cylindricity of long objects. Hence, the measured object is being held between toe bearing units. The cones of the toe bearing units were ground in the complete assembly during movement in order to minimize eccentricity. Vertical movement is provided by a stage comprised of linear guidings directly mounted onto a granite base. A ball screw drive is used for the vertical movement.

Universal test bench for lengths up to 400 mm and Ø 35 mm

Ideal for universal concentricity, circularity and cylindricity testing of sample shafts with optical distance sensor

Accuracy class < 1 µm

High-precision alignment of shaft / linear axis

Synchronization of the two drives

Options:

Extendable travels

Adaptation to the process: sample holder, extension of additional (motorized) X/Y axes

Adapted vibration decoupling

Safety concept and technology (emergency stop, door switch, light grid, laser scanner, STO, SLS)

Individual design with rack, enclosure or integration into the process

Customized development with prototypes, series production

Catalogs

No catalogs are available for this product.

See all of Steinmeyer, Inc.‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.