Linear actuator Z-Phirotaryelectricindustrial

Add to favorites

Compare this product

Characteristics

- Movement

- linear, rotary

- Type

- electric

- Applications

- industrial, storage

- Other characteristics

- precision, positioning, control, integrated, micro, pick-and-place, vacuum, round

- Speed

1,000 m/s

(3,280.84 ft/s)

Description

Linear Rotary Actuator (Z-Phi) with integrated motion control for automated precision assembly

High-precision automated assembly of miniaturized components

This industrial rotary-stroke actuator with integrated pneumatic control allows sensitive as well as very fast combined rotary and linear motion. It is particularly suitable for automated and low-maintenance pick-and-place assembly systems. The rotary stroke enables the removal of the component to be positioned from the automatic magazine feed, detection in position and, if necessary, correction and positioning with controlled contact pressure.

The internal control with field bus interface is plug-and-play ready and is located directly in the positioning unit. In addition, this allows internal storage of error information for automatic compensation. Also integrated is a concept for remote maintenance and remote diagnostics.

Integrated error compensation, remote maintenance and service

Ideal for automated 24/7 production in clean room environments e.g. micro circuit board assembly

Fast, sensitive vertical movement due to direct electric drive

Fully controlled actuation of the entire motion for consistently high product quality

Industrial-grade design: robust, all-round enclosure, low-emission design for cleanroom processes

Low maintenance with exceptionally long lifetime due to integrated vacuum feed-through and internal diagnostic function

Worldwide remote maintenance, diagnostics, updates, programming or parameterization through connection via EtherCAT or CAN

Catalogs

No catalogs are available for this product.

See all of Steinmeyer, Inc.‘s catalogsRelated Searches

- Actuator

- Linear actuator

- Electric actuator

- Industrial actuator

- Rotary actuator

- Precision actuator

- Positioning actuator

- Mini actuator

- Control actuator

- Linear positioning system

- Integrated actuator

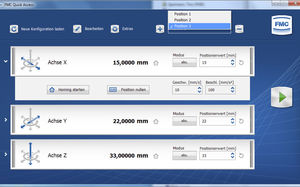

- 3-axis positioning system

- XYZ positioning system

- Ball screw positioning system

- Clean room positioning system

- Combined modules positioning system

- Pick-and-place actuator

- Storage actuator

- Lead screw positioning system

- Vacuum actuator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.