Continuous screwing and assembly system 782300:238.26for screw assembly

Add to favorites

Compare this product

Characteristics

- Operating mode

- continuous

- Applications

- for screw assembly

Description

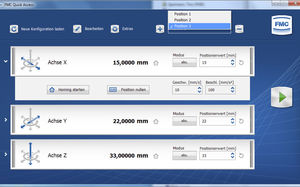

Assembly system for diagnostic imaging systems (ISO 3 clean room) | XY ball screw, AC-Servo

New solutions for imaging diagnostics

These axes are used in alignment machines and are part of an optical measuring and image evaluation system. This allows components and their position to be measured. By precisely approaching and holding the positions, an optical image recognition system can measure distances and provide feedback to other motion systems that adjust and finalize the position to existing systems.

Robust Industrial XY System with Metrology Accuracy

Particles and other contaminants cannot get onto the positioned workpiece

Consistent product quality at high throughput with speeds up to 250 mm/s

Extremely high durability - ideal for continuous industrial operation

Virtually particle-free positioning (ISO Class 3 cleanroom requirement)

Special, hermetically sealed motors with pharmaceutical approval

Optionally expandable:

Various travels per axis

Versions ISO 14644-1 (up to class 1 on request)

Immediate use with pre-configured controller incl. exemplary software

Suitable for demanding environmental conditions

Particles and other contaminants cannot get onto the positioned workpiece

Penetration of cleaning agents during disinfection and cleaning is excluded, for easier cleaning the wiring has been adapted

The parts accessible from the outside are fully nickel-plated and wipeable

Insensitivity to all vibrations and environmental influences due to the use of a stiff ball screw drive

Catalogs

No catalogs are available for this product.

See all of Steinmeyer, Inc.‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.