- Power Transmission - Mechanical components

- Actuator and Positioning System

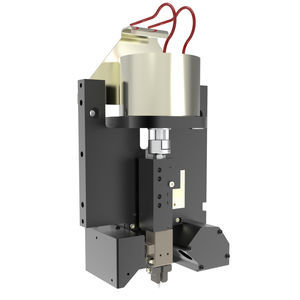

- 3-axis positioning system

- Steinmeyer Mechatronik GmbH

3-axis positioning system 782462:002.26linearfor the semiconductor industryfor wafer handling

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Features

- linear

- Applications

- for the semiconductor industry, for wafer handling

- Other characteristics

- with DC motor, high-resolution, lead screw

- Repeatability

1.5 µm, 5.5 µm

- Stroke

76 mm

(2.99 in)- Speed

50 mm/s

Description

Yield maximization in the smallest possible construction space

This high-precision positioning system has been specifically designed as a complementary polarization filter for miniaturization and automation in EUV lithography. It maximizes the exposure quality as well as the yield of an existing wafer stepper in a very limited space of about 120 x 180 x 31 mm. For this purpose, three independently positionable filters are shifted in the optical system's beam path.It can be used for high-resolution processes under extreme environmental conditions, such as EUV and a dry as well as oxygen-free pure nitrogen atmosphere.

Optimizing accuracy in extreme environments

• Ideal for miniaturization in automated EUV lithography

• Maximizes yield and resolution of existing wafer stepper systems in smallest space (approx. 120 x 180 x 31 mm)

• Accuracies up to 1.5 µm under most extreme environmental conditions: EUV, dry, oxygen-free pure nitrogen atmosphere

• Maintenance-free and flexible 24/7 operation over many 1,000 positioning cycles, distributed over 10 years

Optionally expandable:

• Different travels

• Material selection and vacuum lubrication adapted to the application

• Individual solutions for integration into the customer-specific application

• Version for clean room ISO 14644-1 (up to class 1 on request)

Catalogs

No catalogs are available for this product.

See all of Steinmeyer Mechatronik GmbH‘s catalogsOther Steinmeyer Mechatronik GmbH products

OEM Positioning Systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.