- Power Transmission - Mechanical components

- Actuator and Positioning System

- XYZ positioning system

- Steinmeyer Mechatronik GmbH

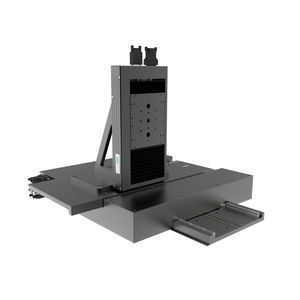

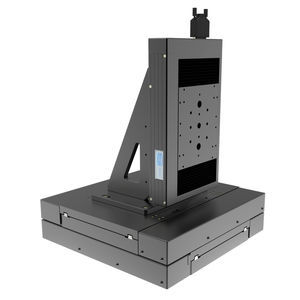

XYZ positioning system 782481:001.26portalfor wafer inspection and metrologyfor microscopy

Add to favorites

Compare this product

Characteristics

- Number of axes

- XYZ

- Features

- portal

- Applications

- for wafer inspection and metrology, for microscopy

- Other characteristics

- large aperture, air bearing, ball screw, with stepper motor

- Repeatability

2.5 µm, 4.5 µm, 5.5 µm, 6.5 µm

Description

XYZ AFM gantry for wafer inspection, microscopy | travel up to 550 x 1550 mm | air bearing, ball screw, belt, stepper motor

Highly stable AFM air bearing gantry with large travel ranges

This very rigid XYZ gantry is specially designed for high-precision atomic force microscopy (AFM) examination of particularly large glass samples. Above the u-shaped sample platform is a movable cantilever in Z for the customized AFM.

The cantilever can be precisely aligned with the sample and moved to any point within the U-shape for surface relief acquisition. The air bearing provides excellent in-plane positioning accuracy. The maximum sample weight is 500 kg.

Atomic stability for demanding measurements

· Ideal for highly rigid and precise measurements without the influence of vibration

· High throughput due to travels of 150 x 275 x 50 mm, expandable to 550 x 1550 x 50 mm

· Extreme stability at standstill of 5 nm and better

· Outstanding long lifetime due to the use of wear-free air bearings

Optionally expandable:

· Integration of further sensors into the process

· Customized adaptation of traverse paths, length combination, cabling and control system

· Feet for additional protection against building vibrations

· Versions for clean room ISO 14644-1 (up to class 1 on request)

· Connections for exhaust

· Special configuration for biotechnology, medical technology, pharmaceuticals, semiconductors

· Optional with pre-configured controller incl. exemplary software for immediate use

Catalogs

No catalogs are available for this product.

See all of Steinmeyer Mechatronik GmbH‘s catalogsOther Steinmeyer Mechatronik GmbH products

Multi Axes Systems: Gantry, Portal, Laboratory Stages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.