- Power Transmission - Mechanical components

- Actuator and Positioning System

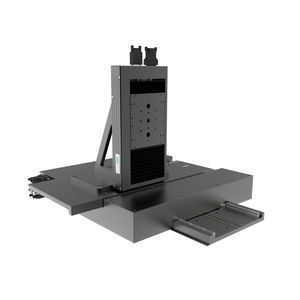

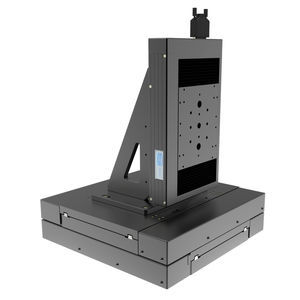

- 3-axis nanopositioning system

- Steinmeyer Mechatronik GmbH

Nanopositioning system for optical applications 782300:130.263-axisXYZlinear

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis, XYZ

- Features

- linear, automatic

- Applications

- for optical applications

- Other characteristics

- ball screw, crossed roller bearing, with DC motor

Description

XYZ positioning system for high precision automated optical inspection | ball screw, cross roller, DC motor, linear measuring system

Highly stable non-contact optical measurement in the submicrometer range

This 3-axis positioning system was developed for high-precision measuring applications in those cases where the XY stage moves the object being measured with extremely low pitch and yaw errors to the sensor or camera on the Z-axis. This is the case, for example, when measuring parts or recording 3D profiles even on tall parts. The XYZ system consists of the durable standard axes of the KT310 cross table and the PMT160 linear table on granite gantry.

Highly accurate and consistent measurement results

· Ideal for high-precision automated inspection processes

· High repeatability up to 0.3 µm

· Reduction of measurement errors to below 3 µm

Flexibly configurable:

· Travels up to 150 mm

· Optionally in different measuring system resolutions

· Rotational movements in combination with DT200

· Flatness-independent interface as well as adjustment options

· Different motor variants: DC motor or stepper motor

· Versions for clean room ISO 14644-1

· Ready-to-use control with pre-configured controller incl. sample software

Catalogs

No catalogs are available for this product.

See all of Steinmeyer Mechatronik GmbH‘s catalogsOther Steinmeyer Mechatronik GmbH products

Multi Axes Systems: Gantry, Portal, Laboratory Stages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.