- Power Transmission - Mechanical components

- Actuator and Positioning System

- 8-axis positioning system

- Steinmeyer Mechatronik GmbH

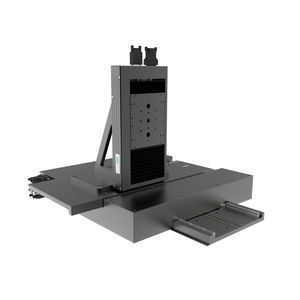

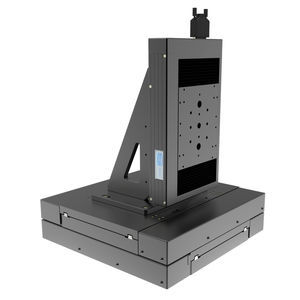

8-axis positioning system 782335:009.26linearrotaryfor laboratory applications

Add to favorites

Compare this product

Characteristics

- Number of axes

- 8-axis

- Features

- linear, rotary

- Applications

- for laboratory applications

- Other characteristics

- compact, manual, high-resolution, ball screw, belt-driven, profiled rail

- Repeatability

2.5 µm

Description

8-axis positioning system for analytics, inspection | XYZ DC motor, ball screw | Phi Theta Omega DC motor, AC servo, Harmonic Drive

High-resolution inspection from 8 angles

This 8-axis positioning system makes it possible to analyze and inspect various sample geometries and other parts. Both cameras / sensors can be tilted above the sample and adjusted in height. In addition, the specimen carrier can be erected by tilting it parallel to the measuring surface to compensate for differences between individual specimens. XY Rz positioning allows the specimen to be evaluated from any angle in spatial radiation pattern by the customized camera.

Compact positioning solution with optimized price-performance ratio

· Ideal for the flexible setup of compact analytical and inspection systems with more than 5 degrees of freedom

· High precision measurement with repeatability down to 2.5 µm / 0.005°

· Stable and rigid construction as a coaxial rotating system, which swivels the cameras / sensors around a common center point

· Low-maintenance and with optimized price-performance ratio due to drive with stepper motor

Optionally expandable:

· Different travels

· Base plate made of aluminum or granite

· Versions ISO 14644-1 (up to class 1 on request)

· Integration into the customer-specific overall application

· Assembly of your complete system with rack, housing and control incl. commissioning with software

Catalogs

No catalogs are available for this product.

See all of Steinmeyer Mechatronik GmbH‘s catalogsOther Steinmeyer Mechatronik GmbH products

Multi Axes Systems: Gantry, Portal, Laboratory Stages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.