- Power Transmission - Mechanical components

- Actuator and Positioning System

- XYZ positioning system

- Steinmeyer Mechatronik GmbH

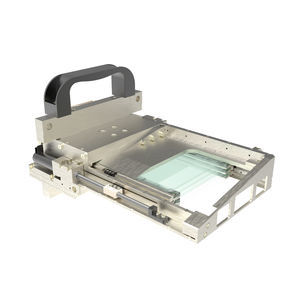

XYZ positioning system 782300:199.264-axislinearfor wafer inspection and metrology

Add to favorites

Compare this product

Characteristics

- Number of axes

- XYZ, 4-axis

- Features

- linear

- Applications

- for wafer inspection and metrology, for clean rooms, PCB

- Other characteristics

- with DC motor, linear motor-driven

Description

XYZ Phi inspection system suitable for 12 inch wafers, printed circuit boards (clean room ISO 2) - Inspection and Mikroscopy

Universal 4-axis granite gantry with cleanroom housing

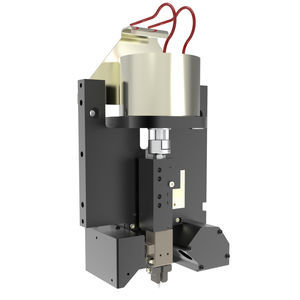

This XYZ Phi positioning system can be used for various test and inspection processes in semiconductor and electronics manufacturing up to cleanroom class ISO 2. Due to the design of the travels up to 320 x 320 mm in XY, it is suitable for all standard wafer sizes up to 12 inches. Samples are manipulated with high precision to a laser, sensor or camera in the Z-axis using the linear motor-driven KT405-320-EDLM mechanical stage. The sensor or camera is adjusted in vertical movement (maximum 50 mm) with the PMT160-050-DC-R/L precision measuring stage, which can optionally be supplemented with a swivel unit..

High-precision testing in demanding cleanrooms

• Ideal for demanding test and inspection processes in semiconductor technology, biotechnology and the pharmaceutical industry

• Fast adaptation to different measurement and testing tasks

• High-precision measurement with repeatability up to 0.3 µm at high speeds up to 100 mm/s

• Safety concept with protective cover

• Emission-free up to clean room ISO class 2

• Delivery of the system with granite base on dampers, steel frame incl. control complete with protective hood and painted housing

Optionally expandable:

• ISO 14644-1 versions (up to class 1 on request)

• Swivel arm for sensor with rotary axis DT200

• Base plate made of granite or aluminum

• Other travels and different samples

• Adaptable for integration into automated processes

• Immediate use with pre-configured controller incl. exemplary software

Catalogs

No catalogs are available for this product.

See all of Steinmeyer Mechatronik GmbH‘s catalogsOther Steinmeyer Mechatronik GmbH products

OEM Positioning Systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.