- Power Transmission - Mechanical components

- Actuator and Positioning System

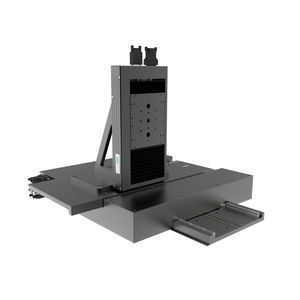

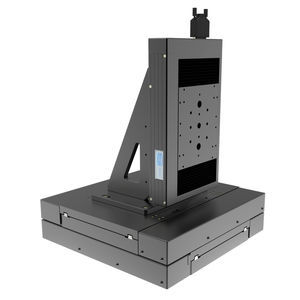

- XYZ positioning system

- Steinmeyer Mechatronik GmbH

XYZ positioning system 782300:150.26.ABlinearverticalhorizontal

Add to favorites

Compare this product

Characteristics

- Number of axes

- XYZ

- Features

- linear, vertical, horizontal, portal

- Applications

- multi-function, for wafer inspection and metrology, optical beam, for the semiconductor industry, for hygienic applications, for clean rooms

- Other characteristics

- for granite slabs, ball screw, linear motor-driven, profiled rail, servo-driven

- Repeatability

1 µm

Description

The gantry design enables highly dynamic movements over an area of 1,000 x 800 mm (adapted to the application and the available space) with a repeatability of 0.3 µm, thus guaranteeing high throughput with consistent quality. In the horizontal XY level, integrated linear motors ensure process speeds of 500 mm/s, while on the vertical Z axis the AC servo achieves values of up to 200 mm/s. The customized processing head or sensor on the Z-axis moves quickly and smoothly over the carriers on the granite. The traverse is suitable for loads up to 10 kg, while the height can vary up to 500 mm depending on the application and component height.

Variety of individual customization options

• Ideal base for inspection systems in semiconductor or optics manufacturing

• Very large travels of 1300 x 800 mm

• Highly dynamic for maximum speeds of up to 1000 mm/s

• Integrated linear motors guarantee high accelerations and speeds with simultaneous high precision

• High-precision and long-life drive in Z through a grinded precision ball screw

• Easy integration or connection to automated handling systems

• Additional casing with integrated extraction or housing for applications up to clean room class ISO 6

Optionally expandable:

• Stackable system design

• Adaptation of travels, length combination, cabling and motion control

• Combination with lifting stages and/or rotary stages for the inspection of complex geometries

• Customized interfaces available for semi-automated or highly-automated semiconductor fabs

• Versions for clean room ISO 14644-1 (up to class 1 on request)

• Immediate use with pre-configured motion controller incl. exemplary software

Catalogs

No catalogs are available for this product.

See all of Steinmeyer Mechatronik GmbH‘s catalogsOther Steinmeyer Mechatronik GmbH products

Multi Axes Systems: Gantry, Portal, Laboratory Stages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.