- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Vacuum manipulator electrictransporthandling

Add to favorites

Compare this product

Characteristics

- Drive type

- electric

- Gripping device

- vacuum

- Applications

- handling, transport

- Domain

- industrial, process, automation

Description

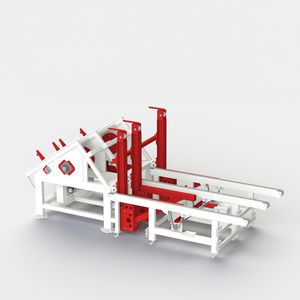

The vacuum manipulator SM-VM 01 finds its application wherever there is a need for automated material handling from edges to the subsequent operation. The material at the edge can be interleaved with stabilizing spacers or spacers in each layer. The manipulator is equipped with a system of large-area vacuum suction cups attached to the lifting and shifting mechanism for transferring individual layers of material to the input conveyor. The conveyor may include a device for separating individual packages.

The SM-VM 01 vacuum manipulator is a versatile lifting device for optimal automation in manufacturing. It allows for safe and reliable handling of even lower quality materials, such as fallen knots, cracks in the material after drying, etc. For manipulation and suction, it utilizes flexible sealing foam (EPDM) and vacuum for both horizontal and vertical material transport. The number of large-area suction cups can be customized according to customer requirements. The manipulator enables handling of roughly cut logs, several-meter-long glued trusses, or chipboards.

Suitable Uses

- for handling boards, beams, wooden panels, or sheets

- for handling objects of various shapes, sizes, or porosity

Main Benefits for Your Production

- increased work efficiency and shorter order fulfillment times

- high precision and accuracy in handling

- easy installation and simple maintenance

- minimization of physical labor when handling heavy materials, thereby preventing health problems caused by lifting and handling heavy loads

- labor force savings

VIDEO

Catalogs

No catalogs are available for this product.

See all of Störi Mantel‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.