- Industrial machines and equipment

- Welding and Assembly

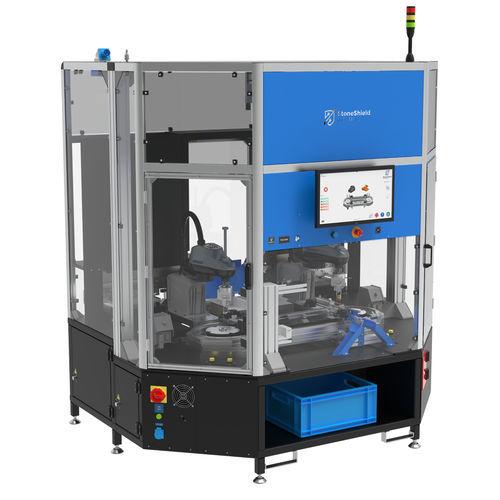

- Robotic assembly machine

- StoneShield - Engineering, LDA

Robotic assembly machine RoCAMfor industrial applicationsflexible

Add to favorites

Compare this product

Characteristics

- Operational mode

- robotic

- Applications

- for industrial applications

- Other characteristics

- flexible

Description

The RoCAM is designed to assembly mini connectors in a fast and flexible way, allowing to change parts to be assembled without need for hardware modifications.

Its uses 2 flexible feeders, that use vision systems to detect the orientation of the parts and 2 Scara robots that pick up the parts and assembly them in a flexible conveyor.

It performs the OK/NOK parts checking using a vision system, automatically sorting the assembled parts to the respective storage.

It includes force and position control to perform the assembly.

Keeping almost the same speed of assembly when comparing with hardware dedicated assembly machines, it allows to use the same machine in different configurations and, more importantly, in new connectors just changing software.

VIDEO

Catalogs

2023 Catalogue

16 Pages

Other StoneShield - Engineering, LDA products

Robotic Solutions

Related Searches

- Mounting machine

- Automatic mounting machine

- Assembly line

- Automated assembly line

- Assembly machine for industrial applications

- Semi-automatic mounting machine

- Flexible assembly machine

- Electronic components assembly machine

- O-ring assembly machine

- Robotic assembly line

- Fully-automatic assembly line

- Robotic assembly machine

- Connector assembly machine

- Cutting solution assembly line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.