- Hydraulics - Pneumatics

- Filter and Separator

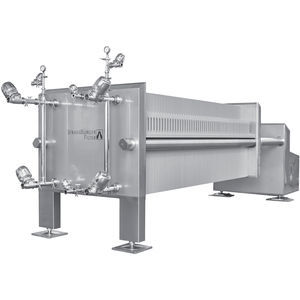

- Frame filter press

- Strassburger Filter GmbH & Co. KG

Plate and frame filter press KFP, MFP seriesmembraneautomaticmobile

Add to favorites

Compare this product

Characteristics

- Type

- membrane, plate and frame

- Operating mode

- automatic

- Other characteristics

- mobile, for wine

- Applications

- for chemicals, beverage

- Chamber volume

Max.: 1,216 l

(321 gal)Min.: 45 l

(12 gal)

Description

Filter presses are pressure filters in which a filter pack formed by filter plates and filter frames or chamber plates is arranged in a frame between a “fixed cover” and a “loose cover.” Filter presses are used in the food and beverage industry and in the chemical, pharmaceutical or environmental sector. There they are often used as laboratory filters, wine filters or juice filters.

One system, many versions

The KFP chamber filter press and the MFP membrane filter press can be used to filter liquids containing solids, drain water from turbid material and sludge or wash filter cake. Diatomaceous earth or perlite is usually used as a filter aid, which is added to facilitate filtration.

The Clean System chamber filter press is available in the following versions:

with membrane plates or chamber plates (as you choose)

as the Clean System for a hermetically sealed and aseptic filter

Standard version of the Clean System chamber filter press

Self-supporting filter frame made of stainless steel

Optionally equipped with membrane plates or chamber plates made of PP

Complete with a peristaltic or piston pump for feeding

Dry-run protection and automatic electrical switching

Pressure compensation tank and required fittings

Manual or electrohydraulic contact pressing

For membrane plates with compressed air connection

We build the optimal filter press for you according to your requirements for the laboratory, technological testing, production or operation. The KFP-C type Clean System features a clean, aseptic, drip-free filter.

Catalogs

No catalogs are available for this product.

See all of Strassburger Filter GmbH & Co. KG‘s catalogsOther Strassburger Filter GmbH & Co. KG products

Products

Related Searches

- Filter housing

- Filtration system

- Cartridge filter housing

- Liquid filter housing

- Filter element

- Liquid filtration system

- Metal filter housing

- Stainless steel filter housing

- Filter press

- Automatic filter press

- Absorption filtration unit

- Liquid filter element

- Automatic filtration system

- Plate and frame filter press

- Fiber filter medium

- Pressure filtration unit

- Stainless steel filtration system

- Chemical filter press

- Food product filter press

- Pharmaceutical product filter press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.