- Industrial machines and equipment

- Furnace and Heat Treatments

- Desulfurization plant

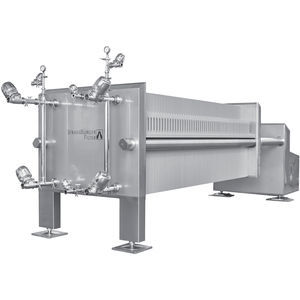

- Strassburger Filter GmbH & Co. KG

Industrial desulfurization plant

Add to favorites

Compare this product

Characteristics

- Applications

- industrial

Description

For the desulfurization of sweet reserve or must, we build desulfurization columns according to the patented STRASSBURGER process – and we do this with glass. This technique has proven to be particularly resistant to aggressive vapors and easy to clean.

The advantages

Exchange column made of glass

Low maintenance and servicing costs

Particularly easy to clean

Does not impair the taste of the must

The heart of the STRASSBURGER desulfurization system, the exchange column, is made of glass due to the aggressive vapors, as are the feed line and the sprinkler, where the highest temperatures are present. The glass parts are particularly easy to clean. Other parts and lines in contact with the product are made of high-alloy chromium steel (V4A). The remaining parts are made of normal chromium steel. The glass column is hung in a pipe frame to provide stability. The patented STRASSBURGER process eliminates the need for a costly vacuum pump and the maintenance and servicing costs are low.

The purest possible lime (e.g. STRASSBURGER special lime), which is prepared in the stirring tank (included in the scope of delivery), ensures gentle desulfurization and trouble-free (residue-free) cleaning of parts that carry lime milk. About 2 kg of lime is consumed per 1,000 liters.

The steam generator and any required cooling unit are not included in the scope of delivery. The system, which is subject to 1 bar pressure during operation, does not require TÜV approval.

Catalogs

No catalogs are available for this product.

See all of Strassburger Filter GmbH & Co. KG‘s catalogsOther Strassburger Filter GmbH & Co. KG products

Products

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.