- Products

- Catalogs

- News & Trends

- Exhibitions

Robotic inspection system RoboScan Lcameralaserscanning

Add to favorites

Compare this product

Characteristics

- Technology

- camera, laser, scanning

- Operational mode

- robotic

- Type

- quality, measurement, for defect detection

- Applications

- for the automotive industry

- Other characteristics

- fast, articulated

Description

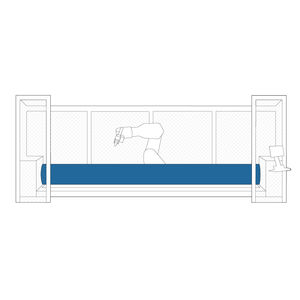

RoboScan L is designed for the quality control needs of small to large sized circular symmetrical parts like passenger car and truck shafts.

RoboScan L provides fast and flexible measurements with high repeatability for horizontally oriented parts up to 2500 mm long.

• Operator friendly user interface with two different software options

• Free access for part clamping allows ergonomic working position

• Fast measurement cycles even for inline measurements

• RoboScan L system consist of standard features, mandatory accessories and options.

Enclosure

The robot is located inside the safety enclosure which houses the entire measurement movement system. The safety cabinet has safety light curtains and an emergency stop system. The electric cabinet is integrated to enclosure.

Robot

• ABB Industrial Robot

• ABB Robot Controller

• ABB Teach Pendant

Measurement programming software

• The measurement programming software takes care of running the robot when programs are created. Creating measurement programs is made easy. The measurement programming software is connected with our ViewScan measurement data analyzing program. The measurement programming software depends on the part to be measured. As standard, there are two options:

• Stresstech Teaching App: suitable for vertically oriented parts like hypoid gears, bearings.

• HTML-based human-machine interface: Suitable for shafts e.g. for measuring camshafts lobes and crankshaft journals.

• Three (3) ready made measurement programs are included with the standard system. More programs can be purchased as options.

VIDEO

Other Stresstech GmbH products

Barkhausen Noise Equipment - Inline/Robot Systems

Related Searches

- Inspection system

- Automated inspection system

- Camera inspection system

- Quality inspection system

- Measurement inspection system

- Defect detection inspection system

- Surface inspection system

- Fast inspection system

- Quality control inspection system

- Inspection system for the automotive industry

- 2D inspection system

- Computer-controlled inspection system

- Surface defect inspection system

- Manual inspection system

- Scanning inspection system

- Laser inspection system

- Robotic inspection system

- Heavy-duty inspection system

- Articulated inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.