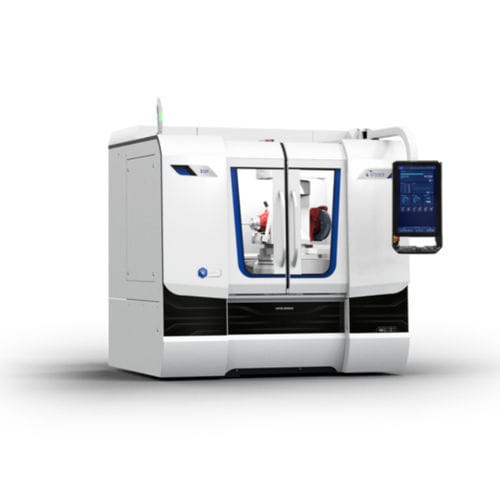

The S121 is a radius internal cylindrical grinding machine. It is the ideal machine for internal, face and external grinding of chuck components. The maximum swing diameter is 300mm (25.6") and the maximum workpiece weight is 100kg (220lbs).

The radius internal cylindrical grinding machine is especially suitable for grinding complex workpieces from very hard materials such as tungsten carbide, ceramics and sapphire as well as for general grinding tasks. It has a host of sophisticated technical features such as the revolutionary StuderGuide® guideway system, high-precision axis drives with linear motors, a fully automatic B-axis with direct drive, etc.

Hardware:

Granitan® S103 mineral casting machine base

StuderGuide® guideway system with linear drive

Fully automatic B-axis with direct drive with a swiveling range from -20° to +91°

Spindle turret with two grinding spindles or one fixed spindle or two spindles in parallel

C-axis for the workhead for form and thread grinding

Full enclosure with two sliding doors

Software:

Simple to use and program thanks to HMI StuderSim

StuderSIM programming and simulation software for the creation and simulation of grinding and dressing programs on the machine control or on an external PC

Standardized interfaces for loader and peripheral devices