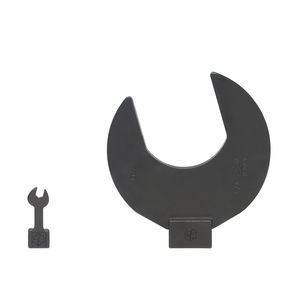

Direct-reading torque wrench M series

Add to favorites

Compare this product

Characteristics

- Other characteristics

- direct-reading

- Torque

Min.: 1 Nm

(0.7 ft.lb)Max.: 410 Nm

(302.4 ft.lb)

Description

Tapered and Flat Beam torque wrenches are excellent choices for any application where:

The ability to visually confirm that the tool is correct before each use is important.

The application is such that the user can see the faceplate of the tool.

Greater accuracy than that provided by clicker torque wrenches is desired.

It is important to know torque variation during rundown, as with prevailing torque nuts.

The need for durability is extremely high.

There is a destructive nature to the application.

Capturing peak torque is important.

These needs are common in aircraft assembly and maintenance operations, fastener testing (in-process/final/receiving inspection) for prevailing torque nuts, and assembly compliance testing for products with rotating components. For these and similar operations, Flat Beam and Tapered Beam torque wrenches are often the best tools for the job.

Related Searches

- Torque wrench

- Screwdriver

- Electric torque wrench

- Ratchet wrench

- Adjustable torque wrench

- Flat screwdriver

- Digital torque wrench

- Phillips screwdriver

- Preset torque wrench

- Torx screwdriver

- Torque multiplier

- Torque screwdriver

- Pozidriv screwdriver

- Manual screwdriver

- Angle/torque torque wrench

- Wireless torque wrench

- Dial torque wrench

- Adjustable screwdriver

- Preset screwdriver

- Micrometer torque wrench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.